Compressed Air System Design for Maximum Efficiency

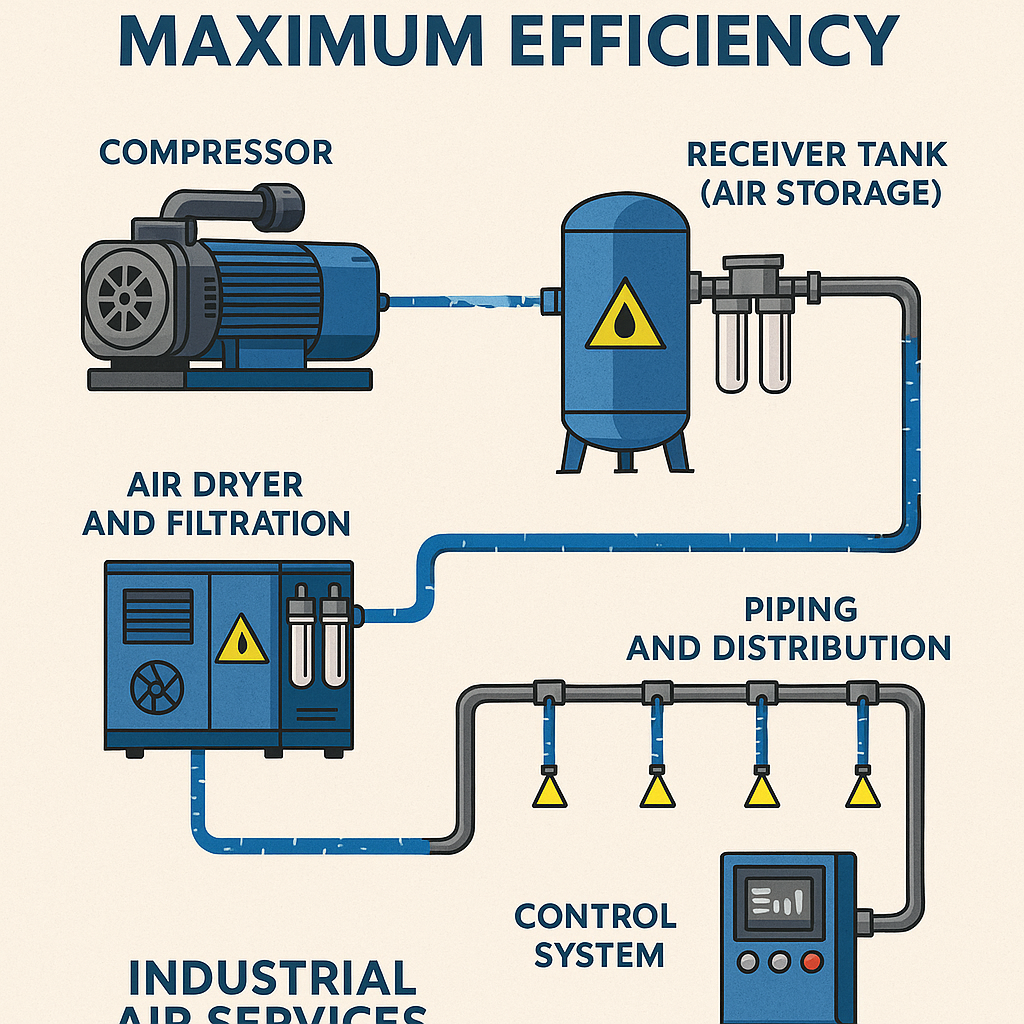

An industrial compressed air system is much more than a compressor sitting in the corner of your facility. It’s a complex network of components—compressors, dryers, receivers, piping, and controls—that must work together seamlessly to power your production line, tools, and automation systems.

Yet, many facilities unknowingly suffer from poor system design, leading to wasted energy, inconsistent pressure, equipment failure, and inflated maintenance costs.

At Industrial Air Services, we help manufacturers across Nashville, Knoxville, Chattanooga, and throughout Central and East Tennessee design and upgrade compressed air systems for peak efficiency, performance, and long-term reliability.

In this guide, we’ll explain what goes into an efficient compressed air system, common pitfalls to avoid, and how proper design can cut your energy bill by 30% or more.

Why System Design Matters

It’s not enough to have the right compressor. If your piping layout causes pressure drops, if your filters clog your flow, or if your storage tank is undersized, your entire operation suffers. An efficient system starts with a plan—and every component plays a role.

Here’s what a poor system design can lead to:

Excessive energy consumption

Short-cycling or overworking the compressor

Frequent breakdowns

Moisture or contamination in the air supply

Inconsistent performance at the point of use

Increased wear on tools and equipment

A properly designed system, on the other hand, delivers clean, consistent, and reliable air—while reducing energy costs and minimizing maintenance.

Core Components of a Compressed Air System

To design an efficient system, each element must be properly selected and integrated. Let’s walk through the major components and how they contribute to overall performance.

1. The Compressor

Whether you’re using a rotary screw, scroll, or reciprocating compressor, the unit must be sized to your application and operated at the correct pressure and duty cycle. Over- or undersizing leads to inefficiencies and premature wear.

If your facility has variable air demand, consider a variable speed drive (VSD) compressor to match output to real-time needs.

2. Air Dryer and Filtration

Moisture and particulates are the enemies of your compressed air system. A quality dryer—refrigerated or desiccant—removes water vapor before it damages downstream equipment. Filtration systems trap oil, dust, and contaminants to ensure clean air reaches your tools.

For industries like food, pharmaceuticals, or paint and coating, Class 0 air quality may be required, which demands an oil-free compressor and advanced filtration.

3. Receiver Tank (Air Storage)

Your air receiver tank helps balance pressure, absorb demand spikes, and reduce cycling of the compressor. The tank should be sized appropriately for your compressor and usage pattern—typically 3 to 10 gallons of storage per CFM of air produced.

Undersized tanks lead to pressure swings and overwork the compressor. Oversized tanks can create delayed response times and take up unnecessary space.

4. Piping and Distribution

This is where many systems lose efficiency. Improperly sized or routed piping creates pressure drops that force compressors to work harder than needed.

Efficient piping design includes:

Proper pipe diameter for your flow rate and distance

Minimal bends and fittings to reduce turbulence

Loop layouts to balance flow and maintain even pressure

Strategic drop legs for moisture control

Smooth interior pipe materials to minimize friction losses

At Industrial Air Services, we custom design piping systems to ensure even distribution of air throughout your facility.

5. Control Systems

Smart controllers and pressure regulators allow your system to adapt in real time, balancing output and energy usage. Sequencing systems are especially useful in facilities with multiple compressors, ensuring the most efficient units run first and minimizing idle time.

Modern monitoring systems also help identify leaks, monitor pressure, and schedule maintenance before problems occur.

System Design Considerations

An efficient compressed air system starts with a deep understanding of how your facility operates. During the design process, we consider:

Peak and average air demand (CFM)

Required pressure levels (PSI)

Hours of operation and shift patterns

Environmental conditions (humidity, heat, dust)

Tool and machine sensitivity

Space constraints for equipment and piping

Future expansion plans

We then create a design that optimizes layout, equipment selection, and energy usage—tailored to your unique needs.

Common Mistakes That Kill Efficiency

Many facilities in Tennessee unknowingly suffer from compressed air system designs that cost them thousands in lost efficiency each year. Here are a few of the most common mistakes we see:

Running compressors at higher pressures than needed

Using undersized or corroded piping

Locating dryers and filters in the wrong sequence

Failing to isolate large air-consuming equipment

Neglecting regular maintenance

Using “temporary” layouts that become permanent bottlenecks

Ignoring system pressure drop measurements

Fixing even one of these issues can lead to major improvements in energy consumption and system stability.

System Design for Tennessee Industries

Our team at Industrial Air Services has extensive experience designing and upgrading systems for:

Food and beverage plants

Automotive suppliers

Pharmaceutical and medical manufacturers

Aerospace components

Plastics molding and packaging

Municipal water and wastewater facilities

Metalworking and fabrication shops

From small operations in Columbia to large-scale production facilities in Chattanooga, we understand the regional demands and local challenges that affect system design in Tennessee.

Serving Nashville, Knoxville, Chattanooga, and Beyond

We proudly provide full system design, installation, and service for businesses across:

Nashville

Knoxville

Chattanooga

Murfreesboro

Lebanon

Columbia

Cookeville

Jackson

Oak Ridge and nearby areas

Whether you’re building a new facility or modernizing an old one, we’ll help you design a system that’s reliable, efficient, and scalable for the future.

Ready to Design a Smarter Air System?

If you’re building, expanding, or frustrated with your current compressed air setup, let the experts at Industrial Air Services help.

We offer:

On-site evaluations and system audits

Custom air system design and layout planning

Equipment sizing and specification

Professional installation and start-up

Ongoing maintenance and monitoring

📞 Call us at (615) 641-3100

📍 Visit us at 138 Bain Drive • LaVergne, TN 37086

💻 Learn more at industrialairservice.com

Design your system right the first time—and reap the savings for years to come.