Understanding Liquid Ring Vacuum Pumps: When and Why to Choose Them

Vacuum technology powers countless industrial processes, from food production to chemical manufacturing to energy generation. Among the many vacuum technologies available, liquid ring vacuum pumps have carved out a special niche for applications that require reliable, durable, and low-maintenance solutions—especially when handling vapor-heavy, wet, or corrosive gases.

Atlas Copco, a global leader in vacuum solutions, offers a full range of liquid ring pumps designed to meet these tough industrial demands. In this blog, we’ll explore what liquid ring pumps are, how they work, when they’re the best choice, and why Atlas Copco’s designs outperform the competition.

📞 Need help choosing the right vacuum technology? Call Industrial Air Services at (615) 641-3100 for expert advice and service across Nashville, Knoxville, and Chattanooga.

How Liquid Ring Vacuum Pumps Work

Liquid ring pumps use a rotating impeller housed eccentrically inside a casing. A sealant liquid—usually water—enters the pump along with the gas to be compressed. As the impeller rotates, centrifugal force throws the liquid outward, creating a rotating liquid ring.

This liquid ring traps pockets of gas between the impeller blades and the casing. As the impeller continues rotating, these pockets are compressed and pushed toward the discharge port.

Key characteristics of liquid ring operation include

Handling large volumes of vapor without contamination

Ability to compress saturated gases without condensation issues

Resilience to liquid carryover without damage

Simple, robust design with very few moving parts

Because of these properties, liquid ring pumps thrive in wet, dirty, and corrosive environments where other vacuum technologies might struggle.

When to Choose a Liquid Ring Vacuum Pump

Liquid ring pumps are not ideal for every application, but in the right environment, they offer unbeatable advantages.

Choose a liquid ring pump when

The process gas contains significant moisture or vapor

Corrosive or chemically reactive gases are present

High reliability is critical in challenging conditions

Oil-free operation is important (when water is used as the sealing fluid)

Low noise and smooth operation are desired

They are especially useful in industries like

Chemical processing (vapor recovery, distillation)

Pulp and paper (dewatering, vacuum forming)

Power generation (steam turbine evacuation)

Food and beverage (de-aeration, vacuum packaging)

Oil and gas (flare gas recovery, refining)

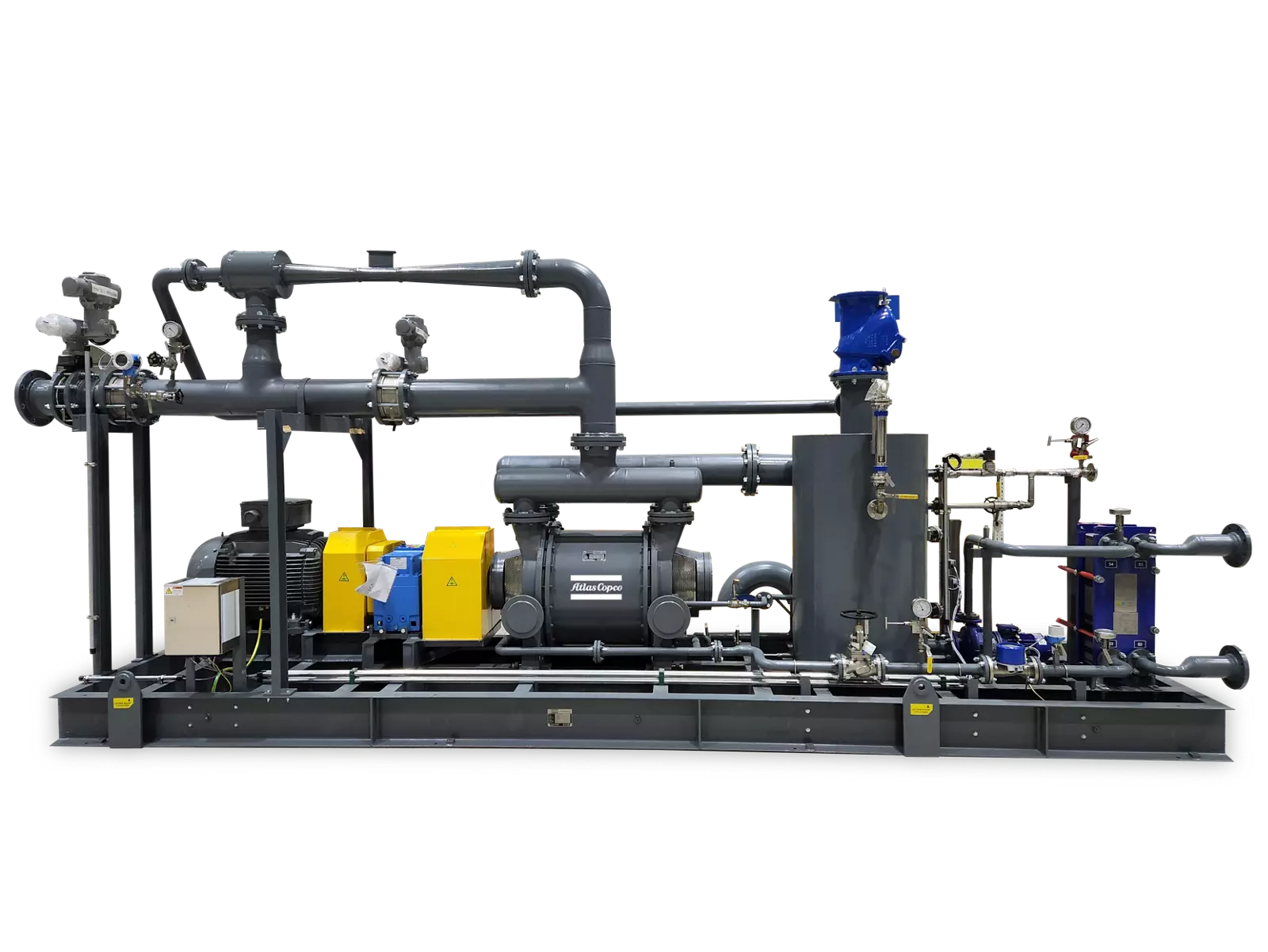

Atlas Copco’s Liquid Ring Vacuum Pump Series

Atlas Copco’s range of liquid ring pumps includes

AWL Series: Compact, single-stage liquid ring pumps designed for wet processes and moderate vacuum levels

AWS Series: Standard two-stage pumps optimized for deeper vacuum levels and higher gas throughput

AWD Series: Heavy-duty two-stage pumps for demanding, corrosive, or high-temperature applications

AWC Series: Custom-configured systems combining pumps, separators, and control panels for turnkey installation

Each series is engineered for maximum uptime, efficiency, and flexibility. Pumps are available with a range of materials of construction including stainless steel, bronze, and cast iron to handle corrosive or abrasive gases.

Advantages of Atlas Copco Liquid Ring Pumps

Robust Construction

Atlas Copco designs their liquid ring pumps with heavy-duty components, including corrosion-resistant casings and impellers, to extend service life even in the harshest environments.

High Efficiency

Modern design optimizations such as improved impeller profiles and optimized fluid flow channels increase volumetric efficiency and reduce energy consumption.

Quiet Operation

Liquid ring pumps operate with smooth, continuous compression, resulting in much quieter noise profiles than other types of vacuum pumps.

Minimal Maintenance Requirements

With fewer moving parts, no internal metal-to-metal contact, and simple mechanical seals, Atlas Copco liquid ring pumps require very little preventive maintenance compared to dry screw or oil-sealed rotary vane pumps.

Flexible Fluid Options

While water is the most common sealing liquid, Atlas Copco pumps can be configured to operate with specialized fluids such as glycol, solvents, or oils depending on the application.

Real-World Example: Chemical Recovery Plant in Alabama

A specialty chemical manufacturer in Alabama needed a vacuum system for recovering solvent vapors from a batch distillation process. The gas stream contained high moisture content and traces of corrosive acids.

Industrial Air Services evaluated the process and installed two Atlas Copco AWD Series liquid ring vacuum pumps, constructed with stainless steel wetted parts for corrosion resistance.

Results after 18 months

Zero unscheduled maintenance events

Consistent vacuum levels even with fluctuating load

Reduced energy consumption compared to legacy pumps

Solvent recovery rates increased by 12% due to stable vacuum

📞 Considering a liquid ring system for your process? Call Industrial Air Services at (615) 641-3100 for a consultation.

While dry screw pumps are more energy-efficient in dry gas applications, liquid ring pumps dominate when moisture, wet vapors, and dirty gases are involved.

Maintenance Tips for Liquid Ring Pumps

To maximize the life and efficiency of a liquid ring pump

Use clean sealant liquid (filtered water or treated fluid)

Monitor sealant temperature to prevent overheating

Inspect and maintain mechanical seals periodically

Flush the pump when handling sticky or corrosive media

Follow Atlas Copco’s recommended service intervals and use OEM parts

Industrial Air Services offers preventive maintenance contracts to keep your vacuum system operating at peak performance.

Why Choose Industrial Air Services for Liquid Ring Vacuum Solutions

Industrial Air Services is your trusted source for Atlas Copco liquid ring pumps across Tennessee. Our services include

On-site vacuum audits and system design

Pump sizing and materials consultation

Installation and commissioning

Preventive maintenance and emergency service

OEM parts, rebuild kits, and fast repair turnaround

Our experienced team ensures your system is designed right, installed correctly, and maintained for long-term success.

📞 Need a quote or system evaluation? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Liquid ring vacuum pumps offer unbeatable performance in applications with vapor, moisture, and corrosive gases. Atlas Copco’s AWL, AWS, AWD, and AWC series pumps deliver rugged reliability, low maintenance, and efficient operation. Whether you're upgrading a system or installing new equipment, Industrial Air Services has the expertise to design and support a liquid ring vacuum solution perfectly matched to your needs.

Contact Industrial Air Services at (615) 641-3100 today to schedule a site evaluation or discuss how liquid ring technology can improve your operations in Nashville, Knoxville, or Chattanooga.

Custom Vacuum Systems: How Atlas Copco Engineers Tailor Solutions for Every Industry

When it comes to industrial vacuum systems, a one-size-fits-all approach rarely delivers the best results. Every manufacturing process, plant layout, and operational demand is different. That's why custom vacuum systems have become increasingly important for companies that prioritize energy efficiency, reliability, and production quality.

Atlas Copco has long recognized this need for customization. Their Systems + Solutions engineering group works with businesses across industries to design vacuum systems specifically tailored to each customer’s processes, environment, and goals.

In this blog, we'll dive into why custom vacuum solutions are crucial, how Atlas Copco delivers them, and why Industrial Air Services is your best partner for designing and supporting a system that works for you.

📞 Ready to discuss your custom vacuum needs? Call Industrial Air Services at (615) 641-3100 today. We proudly serve Nashville, Knoxville, and Chattanooga.

The Problem with Off-the-Shelf Vacuum Systems

Prepackaged, off-the-shelf vacuum systems are convenient—but they rarely provide optimal performance.

Common problems with cookie-cutter solutions include

Oversized or undersized systems wasting energy

Insufficient redundancy leading to costly downtime

Space conflicts with existing plant layouts

Poor integration with plant controls (SCADA, PLC)

Failure to meet industry-specific standards for cleanliness or safety

Every facility has unique factors such as operating hours, flow requirements, pressure ranges, environmental conditions, available floor space, and long-term production goals. A poorly matched vacuum system can lead to excessive energy bills, equipment failures, and lost production.

What Is a Custom Vacuum System?

A custom vacuum system is an engineered solution designed specifically around your facility’s needs. This might include

Selecting the best pump technology (dry, oil-sealed, liquid ring)

Sizing the pumps accurately for your flow and pressure needs

Designing a centralized or distributed vacuum system layout

Incorporating redundancy for mission-critical applications

Custom control panels, VFDs, and automation integration

Skid-mounted systems for easy installation

Noise reduction strategies through acoustic enclosures or remote installation

Atlas Copco’s Systems + Solutions team specializes in building these engineered vacuum systems for industries like food and beverage, chemical processing, electronics manufacturing, plastics, energy production, and pharmaceuticals.

Why Atlas Copco Leads in Custom Vacuum Systems

Atlas Copco brings major advantages to custom system engineering, including

Industry-Leading Technology

Atlas Copco’s vacuum pumps include innovations like

VSD⁺ (Variable Speed Drive) for massive energy savings

HEX@™ smart control interfaces

GENIUS Instant Insights™ cloud-based monitoring

Energy recovery options to capture heat for reuse

Whether you need oil-sealed rotary screw pumps, dry screw pumps, claw pumps, or liquid ring technology, Atlas Copco offers best-in-class solutions.

Application-Specific Engineering

Atlas Copco’s engineers don’t just sell products—they analyze your entire vacuum demand curve, production schedule, and layout constraints. They model system performance under real-world conditions to maximize efficiency and reliability.

Energy Optimization

Custom systems are designed to minimize energy waste. Variable speed operation, intelligent pump staging, and real-time load adjustment ensure you use only the energy you need—leading to lower operating costs and a faster ROI.

Scalability and Flexibility

Atlas Copco systems are designed to grow with you. Need to expand production next year? No problem. Custom systems allow for additional pumps or automated load sharing without major redesigns.

Integrated Monitoring and Remote Management

Atlas Copco’s GENIUS Instant Insights™ platform enables 24/7 remote monitoring, predictive maintenance alerts, and real-time system performance reporting—keeping your operation ahead of problems.

Real-World Example: Centralized Vacuum System for a Bottling Plant

A regional beverage manufacturer needed to upgrade their vacuum supply for bottling and packaging lines. Their legacy decentralized system featured multiple small pumps scattered across the facility, causing

High energy costs from inefficient operation

Noise problems on the production floor

Frequent pump failures with no backup redundancy

Industrial Air Services worked with Atlas Copco’s Systems + Solutions team to design a centralized vacuum system featuring

Three GHS VSD⁺ rotary screw vacuum pumps with intelligent load sharing

Custom stainless steel piping network with isolation valves

Remote monitoring and alert system through GENIUS platform

Energy recovery system to capture and reuse waste heat

Results included

38% reduction in total system energy consumption

Noise reduction of 12 dB on the production floor

Zero production downtime from vacuum failures

Payback period of less than two years

📞 Want a customized system assessment? Call Industrial Air Services at (615) 641-3100.

Industries That Benefit from Custom Vacuum Systems

Atlas Copco’s tailored vacuum solutions are trusted across industries like

Food and Beverage Processing (bottling, canning, MAP packaging)

Pharmaceutical and Biotech Manufacturing (sterile transfer, freeze drying)

Plastics and Rubber (extrusion, molding, degassing)

Semiconductor Fabrication (wafer processing, chip manufacturing)

Paper and Pulp Production (sheet forming, dewatering)

Energy and Power (transformer drying, turbine manufacturing)

Every sector has unique vacuum demands, and a custom system ensures that your process operates efficiently and reliably.

Key Components of a Custom Vacuum System

A complete Atlas Copco custom system typically includes

Correctly sized vacuum pumps (dry, oil-sealed, or liquid ring)

Centralized or distributed piping networks

Backup redundancy and isolation valves

Customized PLC or HMI controls with HEX@™ interface

Energy-saving VSD⁺ drives and smart sequencing

Remote monitoring and predictive maintenance features

Optional acoustic enclosures and vibration dampening

By engineering the entire system, not just the pumps, Atlas Copco delivers solutions that are greater than the sum of their parts.

How Industrial Air Services Helps Design Your Custom Solution

At Industrial Air Services, we don’t believe in selling products—we believe in delivering solutions that work.

Our custom vacuum system services include

On-site plant walkthroughs and vacuum demand assessments

System modeling and energy savings calculations

Full engineering design with CAD drawings and performance simulations

Installation, commissioning, and startup support

Preventive maintenance programs to protect your investment

24/7 service and emergency support across Tennessee

From design to implementation, we ensure that your Atlas Copco custom vacuum system is perfectly matched to your needs and fully optimized for performance and reliability.

📞 Ready to explore a custom-designed vacuum solution? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Custom vacuum systems offer unmatched advantages in energy efficiency, process reliability, and long-term operational savings. Atlas Copco’s engineering expertise, paired with Industrial Air Services’ local support, ensures that your facility gets a vacuum system that’s not only effective—but also future-proof.

Industrial Air Services proudly serves the Nashville, Knoxville, and Chattanooga regions as your trusted partner for Atlas Copco vacuum solutions. Contact us today at (615) 641-3100 to schedule a site evaluation or discuss your custom vacuum needs.

Energy-Efficient Vacuum Solutions: How Variable Speed Drive (VSD⁺) Pumps Save You Money

Energy costs are one of the largest operational expenses for industrial facilities, especially for systems that run continuously—like vacuum pumps. In the past, vacuum pumps operated at a constant speed regardless of process demand, wasting tremendous amounts of energy. But modern facilities can no longer afford inefficiency.

That’s why Variable Speed Drive (VSD⁺) vacuum technology, pioneered by companies like Atlas Copco, has become a game-changer across manufacturing, food processing, plastics, packaging, and energy production.

In this blog, we’ll explore how energy-efficient VSD⁺ vacuum pumps work, why they save facilities tens of thousands of dollars annually, and how partnering with Industrial Air Services ensures you get the right energy-saving solution.

📞 Ready to cut your energy bills? Call Industrial Air Services at (615) 641-3100 for sales and service across Nashville, Knoxville, and Chattanooga.

The Problem with Traditional Fixed-Speed Vacuum Pumps

Traditional vacuum pumps are designed to run at full speed whenever they are operating—whether maximum vacuum is required or not. This leads to:

Constant energy consumption

Frequent cycling (on/off), causing wear

Unnecessary maintenance

High peak electrical loads

Overheating and shortened lifespan

Even processes with variable demand—such as fluctuating production lines or multiple shift schedules—still ran pumps at full tilt. This wastes enormous amounts of electricity and reduces equipment reliability.

How VSD⁺ Vacuum Technology Works

Variable Speed Drive (VSD⁺) technology allows the motor speed of the vacuum pump to automatically adjust based on real-time process demand.

If less vacuum is needed, the motor slows down, consuming only the energy required to maintain set pressure. When more vacuum is needed, the pump speeds up to match.

Atlas Copco’s vacuum products, including the GHS VSD⁺ oil-sealed rotary screw pumps and the DWS VSD⁺ dry screw pumps, integrate VSD⁺ as standard—offering unmatched flexibility and energy savings.

Key features include:

Fully automated motor speed adjustments

Precise setpoint control (target pressure maintenance)

Soft start and stop, reducing mechanical stress

Integrated smart monitoring with HEX@™ and GENIUS Instant Insights™

How Much Energy Can You Save?

The energy savings from switching to VSD⁺ vacuum pumps are dramatic.

Industry studies and real-world Atlas Copco case studies show:

Up to 50% reduction in energy costs versus traditional fixed-speed pumps

35% longer service intervals due to reduced mechanical wear

Up to 70% reduction in peak electrical demand charges

For a mid-sized manufacturing facility running multiple vacuum pumps, these savings could amount to $15,000 to $100,000 per year depending on usage.

Plus, reduced energy consumption supports corporate sustainability goals and carbon footprint reduction.

Real-World Example: Plastics Extrusion Plant in Tennessee

A plastics manufacturer operating three legacy oil-sealed vacuum pumps was facing high energy bills and costly maintenance cycles.

They upgraded to three Atlas Copco GHS 585 VSD⁺ rotary screw vacuum pumps.

Results after 12 months:

47% reduction in vacuum system energy usage

Payback period of just under 18 months

32% reduction in unplanned maintenance events

Carbon footprint cut by 60 metric tons per year

📞 Interested in an energy savings audit? Call Industrial Air Services at (615) 641-3100 to schedule one.

VSD⁺ Pumps Improve More Than Just Energy Efficiency

1. Improved Product Quality

Constant vacuum levels mean better consistency in processes like packaging, degassing, freeze-drying, and semiconductor manufacturing.

VSD⁺ pumps deliver steady pressure without fluctuations that can damage products or processes.

2. Reduced Mechanical Stress

Soft starts and optimized speeds mean bearings, seals, and rotors last longer. There’s less vibration, less heat, and far fewer emergency shutdowns.

3. Flexible Operation

If your production volume changes seasonally, daily, or shift-to-shift, VSD⁺ pumps automatically adjust—no manual intervention needed.

This flexibility is essential for industries like food packaging, bottling, plastics, textiles, and electronics.

4. Quieter Work Environments

Atlas Copco’s VSD⁺ vacuum pumps operate with significantly lower noise levels, improving conditions for plant workers and reducing the need for costly acoustic enclosures.

Which Atlas Copco VSD⁺ Vacuum Pumps Are Available?

Atlas Copco offers a full range of VSD⁺ equipped vacuum pumps to fit every industry:

GHS VSD⁺ Series: Oil-sealed rotary screw pumps for packaging, plastics, woodworking, and general industry

DWS VSD⁺ Series: Dry screw pumps for food, pharmaceutical, and semiconductor applications

LRP VSD⁺ Series: Liquid ring pumps for wet and vapor-heavy processes like power generation and chemical manufacturing

DHS 065-200 VSD⁺: Dry screw pumps for clean manufacturing, R&D, and battery production

Each pump is engineered with Atlas Copco’s signature smart control systems (HEX@™) and remote monitoring (GENIUS Instant Insights™) to further optimize performance.

VSD⁺ and Sustainability: A Win-Win

VSD⁺ technology directly supports environmental goals by:

Reducing energy waste

Lowering carbon emissions

Extending equipment lifespan

Reducing the environmental impact of oil and filter disposal

Facilities investing in Atlas Copco VSD⁺ vacuum systems often qualify for energy efficiency incentives, rebates, and carbon reduction credits—providing an additional financial benefit.

How Industrial Air Services Supports Your VSD⁺ Upgrade

Choosing the right vacuum pump isn't just about the brand—it’s about having the right partner.

Industrial Air Services offers:

On-site vacuum audits to assess potential savings

System sizing and application engineering

Turnkey installation and commissioning

Preventive maintenance programs to protect your investment

24/7 emergency support and fast access to OEM parts

Whether you’re replacing a single unit or upgrading an entire facility, our team ensures your VSD⁺ investment delivers maximum returns.

📞 Ready to start saving energy and money? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Atlas Copco’s VSD⁺ vacuum technology represents a major leap forward in energy efficiency, reliability, and sustainability. By matching vacuum output to real-time demand, these smart systems deliver massive energy savings, reduced maintenance, and better process control.

Industrial Air Services proudly supplies and supports Atlas Copco’s full range of VSD⁺ vacuum pumps across Nashville, Knoxville, and Chattanooga. If you're ready to lower your energy bills and future-proof your vacuum systems, our experts are ready to help.

📞 Call Industrial Air Services today at (615) 641-3100 to learn more or schedule your energy savings audit.

Oil-Sealed vs. Dry Vacuum Pumps: Choosing the Right Technology for Your Application

Industrial vacuum pumps are essential across manufacturing, pharmaceuticals, electronics, food packaging, and energy production. However, not all vacuum pumps are created equal—and choosing the wrong type can mean higher energy costs, more frequent maintenance, and even process contamination.

Two of the most common categories are oil-sealed vacuum pumps and dry vacuum pumps. Each has unique strengths and ideal applications. In this blog, we’ll break down the differences between these two technologies, help you understand which is best for your operation, and highlight how Atlas Copco’s innovative vacuum solutions offer unmatched performance.

📞 Need expert advice on vacuum pump selection? Call Industrial Air Services at (615) 641-3100 for service across Nashville, Knoxville, and Chattanooga.

What Are Oil-Sealed Vacuum Pumps?

Oil-sealed vacuum pumps (such as rotary vane and rotary screw designs) use a thin film of oil to seal, lubricate, and cool internal components. The oil also helps maintain a consistent vacuum level and reduces internal leakage.

Atlas Copco’s GHS VSD⁺ series is a prime example of modern oil-sealed rotary screw vacuum pumps.

Key Features:

High ultimate vacuum levels (down to a few millibar absolute)

Efficient cooling and sealing properties from oil

Excellent for processes with demanding vacuum stability requirements

Long service intervals when properly maintained

Oil-sealed pumps have traditionally been the workhorses of industrial vacuum, offering robust performance in applications where contamination risks are low or manageable.

What Are Dry Vacuum Pumps?

Dry vacuum pumps achieve vacuum without any oil or liquid in the compression chamber. Designs include dry screw, dry claw, scroll, and multistage roots pumps.

Atlas Copco’s DWS VSD⁺ and DZS Claw Series pumps are leading examples of dry vacuum solutions.

Key Features:

No risk of process contamination by oil

Lower maintenance and operating costs

Environmentally friendly operation (no oil disposal required)

Excellent for cleanroom and sensitive manufacturing environments

Dry vacuum pumps have surged in popularity due to stricter contamination controls, sustainability goals, and lower total cost of ownership.

When to Choose Oil-Sealed Vacuum Pumps

Oil-sealed technology remains the best choice for certain applications where:

High vacuum levels are critical (below 1 mbar)

Fluctuating loads are minimal

Moderate contamination risk is acceptable

Cost-conscious operations are important

Common industries and applications:

Plastics extrusion

Vacuum packaging

CNC woodworking

Bottle filling

Automotive vacuum impregnation

Atlas Copco’s GHS VSD⁺ series delivers energy-efficient, oil-sealed performance with integrated VSD technology—optimizing performance while cutting energy use up to 50%.

When to Choose Dry Vacuum Pumps

Dry pumps are the clear winner when:

Oil contamination cannot be tolerated (pharma, semiconductor)

Clean environments like ISO Class cleanrooms are required

Energy savings and sustainability are top priorities

Frequent cycling and load variation are common

Common industries and applications:

Pharmaceutical manufacturing (coating, freeze drying)

Semiconductor and electronics (wafer fabrication)

Food packaging (MAP packaging, dairy filling)

Battery production (lithium-ion cells)

Research labs and biotechnology

Atlas Copco’s DWS VSD⁺ dry screw pumps and DZS dry claw pumps offer rugged, oil-free performance ideal for sensitive processes.

Why Variable Speed Drive (VSD⁺) Changes the Game for Both Types

Whether you choose oil-sealed or dry, Atlas Copco’s VSD⁺ technology delivers major benefits:

Energy savings up to 50%

Quieter operation

Lower heat output

Extended equipment life

Built-in smart control and remote monitoring

By automatically adjusting the motor speed based on demand, VSD⁺ minimizes waste and protects your investment.

Real-World Example: Choosing the Right Pump in Food Processing

A meat processing plant needed vacuum pumps for two very different parts of its facility:

Packaging area: Required moderate vacuum for modified atmosphere packaging (MAP) with frequent cycling.

Brine injection station: Required strong, steady vacuum for marination and injection.

Solution: They installed DZS dry claw pumps for the packaging line to eliminate oil contamination and maximize cycling efficiency. For the brine injection system, they installed GHS VSD⁺ oil-sealed rotary screw pumps to ensure strong, stable vacuum at maximum energy efficiency.

Result:

38% energy savings across the vacuum system

Zero contamination issues

Reduced maintenance frequency by 40%

📞 Need a custom recommendation like this? Call Industrial Air Services at (615) 641-3100.

How Atlas Copco Supports Both Technologies

Atlas Copco’s vacuum solutions include:

Oil-Sealed Systems: GHS VSD⁺ rotary screw, LRP VSD⁺ liquid ring pumps

Dry Systems: DWS VSD⁺ dry screw, DZS dry claw pumps, DHS 065-200 VSD⁺ dry screw pumps

Connectivity: GENIUS Instant Insights™ and HEX@™ smart control

Custom Systems: Engineered Systems + Solutions for complex applications

By offering both oil-sealed and dry options—with VSD⁺ as standard—Atlas Copco ensures customers get the best match for their needs.

Final Tips for Choosing the Right Vacuum Pump

Analyze your process requirements carefully: Is ultimate vacuum, contamination control, or energy savings the top priority?

Consider total cost of ownership, not just upfront purchase price.

Factor in maintenance schedules, spare parts, and service availability.

Look for systems with built-in monitoring to protect your investment.

Partner with an expert distributor who can size and configure your system properly.

Conclusion

Choosing between oil-sealed and dry vacuum technology is one of the most important decisions you’ll make for your industrial process. With Atlas Copco’s broad portfolio of GHS, DWS, and DZS pumps—and expert support from Industrial Air Services—you can be confident you’re selecting a vacuum solution that maximizes reliability, minimizes costs, and supports your future growth.

This blog is proudly provided by Industrial Air Services, your trusted source for Atlas Copco vacuum systems in Nashville, Knoxville, and Chattanooga.

📞 For help sizing and selecting your next vacuum pump, call (615) 641-3100 today.

The Evolution of Industrial Vacuum Technology: How Atlas Copco Is Leading the Future

Industrial vacuum technology has come a long way from the early days of bulky, inefficient pumps. Today, vacuum systems are the backbone of critical industries like pharmaceuticals, electronics manufacturing, food processing, energy production, and plastics. Modern industrial processes demand vacuum solutions that are energy-efficient, smart, customizable, and sustainable.

At the forefront of this evolution stands Atlas Copco, a global leader known for pioneering innovations that continue to shape the vacuum landscape. In this article, we'll take a closer look at how industrial vacuum technology has evolved—and how Atlas Copco is driving the future with cutting-edge systems like HEX@™, GENIUS Instant Insights™, and Variable Speed Drive (VSD⁺) vacuum pumps.

📞 Need help selecting the right vacuum system for your operation? Call Industrial Air Services at (615) 641-3100 for expert assistance across Nashville, Knoxville, and Chattanooga.

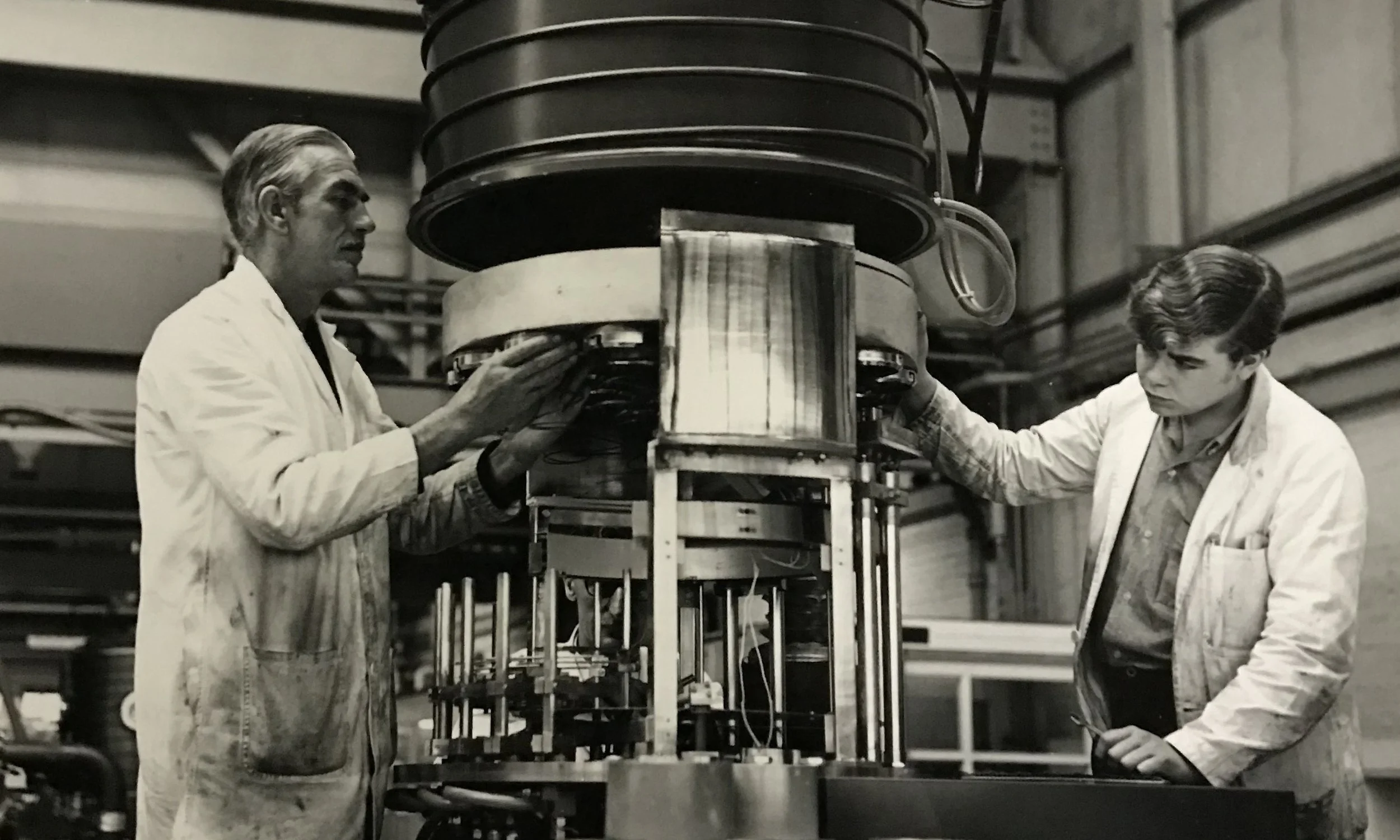

A Brief History of Industrial Vacuum Pumps

Vacuum technology dates back centuries, but industrial applications began in earnest in the 20th century with the rise of mass manufacturing. Early vacuum pumps were primarily oil-sealed rotary vane designs, delivering reliable performance but often requiring significant maintenance and energy.

Key milestones include:

1950s: Introduction of oil-sealed rotary vane pumps for manufacturing.

1970s: Development of dry screw and claw pumps, offering oil-free operation.

1990s: Variable Speed Drive (VSD) technology emerges, improving efficiency in air compressors—and eventually vacuum pumps.

2010s: Connectivity, smart monitoring, and predictive maintenance become available for vacuum systems.

Today, leading manufacturers like Atlas Copco offer sophisticated, application-specific vacuum solutions that maximize efficiency, sustainability, and uptime.

Atlas Copco’s Role in Transforming Vacuum Technology

Atlas Copco’s commitment to innovation has redefined industrial vacuum systems. Let’s explore some key ways they are advancing the industry:

1. Variable Speed Drive (VSD⁺) Vacuum Pumps

Traditionally, vacuum pumps operated at a fixed speed, regardless of the actual demand. This meant wasted energy, frequent cycling, and premature wear.

Atlas Copco’s VSD⁺ technology changed that by allowing the pump’s motor speed to adjust automatically to the process demand. This results in:

Energy savings up to 50%

Reduced maintenance intervals

Lower operating temperatures

Longer equipment life

The GHS VSD⁺ Series of rotary screw vacuum pumps and DWS VSD⁺ Dry Screw Pumps are excellent examples of how variable speed vacuum pumps have revolutionized industries like plastics extrusion, woodworking, bottling, and food packaging.

2. HEX@™: Smart Vacuum Control at Your Fingertips

Efficiency isn’t just about hardware—it’s also about control. Atlas Copco’s HEX@™ platform provides a new generation of human-machine interface for vacuum pumps.

Features include:

Easy access to pump status, performance trends, and diagnostics

Remote monitoring capabilities

Customized control over operating parameters

Integration with plant automation and MES/SCADA systems

With HEX@™, operators can fine-tune vacuum performance to match exact process needs—saving energy and reducing the risk of failure.

3. GENIUS Instant Insights™

Predictive maintenance is the future of industrial reliability, and Atlas Copco leads the way with GENIUS Instant Insights™.

GENIUS is a cloud-based monitoring platform that connects to Atlas Copco vacuum pumps, providing:

Real-time system status

Maintenance reminders and alerts

Energy consumption reports

Early warnings of potential problems

This proactive approach allows facilities to fix small issues before they become big failures, dramatically improving uptime and reducing emergency repair costs.

4. Tailor-Made Systems: Systems + Solutions

Not all facilities have the same vacuum needs. That’s why Atlas Copco offers custom engineering through its Systems + Solutions service.

Custom solutions may include:

Centralized vacuum systems

Redundancy for critical applications

Skid-mounted units for space-constrained environments

Custom PLC integration

These tailored solutions ensure that customers get exactly the performance they need—without over- or under-sizing equipment.

How Vacuum Technology Is Supporting Sustainability Goals

Sustainability is no longer optional—it's a mandate. Modern vacuum systems must align with global efforts to cut carbon emissions and reduce environmental impact.

Atlas Copco’s innovations help companies achieve:

Lower energy consumption: VSD⁺ and intelligent control mean less wasted energy.

Reduced oil and water usage: Dry vacuum pumps eliminate oil contamination and water sealing needs.

Minimized downtime: Predictive maintenance reduces the environmental impact of emergency production shutdowns.

Smaller carbon footprints: More efficient vacuum systems contribute to corporate ESG goals.

By investing in smart, energy-saving vacuum technology, companies can not only save money but also meet growing environmental regulations.

Industry Applications Where Atlas Copco Excels

Atlas Copco’s vacuum solutions serve a wide range of industries, including:

Pharmaceuticals: Cleanroom-compatible dry pumps for sterile production.

Electronics and Semiconductor Manufacturing: Ultra-clean, oil-free vacuum systems critical for chip fabrication.

Food and Beverage: Hygienic vacuum for packaging, filling, and preserving freshness.

Plastics and Rubber: Vacuum forming and extrusion applications.

Power and Energy: Degassing and insulation production for turbines and transformers.

Printing and Packaging: Consistent vacuum for printing presses and flexible packaging machines.

Across each sector, Atlas Copco’s vacuum innovations offer measurable improvements in energy efficiency, reliability, and process quality.

A Look at Key Product Lines

Here are just a few highlights of Atlas Copco’s broad vacuum portfolio:

GHS VSD⁺ Series: Energy-efficient oil-sealed rotary screw vacuum pumps.

DWS VSD⁺ Series: High-performance dry screw vacuum pumps.

LRP VSD⁺ Series: Liquid ring pumps designed for vapor-heavy and wet applications.

DZS Series: Compact dry claw pumps with low noise and high durability.

AWC/AWS/AWL Series: Robust liquid ring vacuum pumps for harsh environments.

No matter the process or environmental conditions, there’s an Atlas Copco vacuum solution to fit.

📞 Need help determining which system is right for your operation? Call Industrial Air Services at (615) 641-3100.

Future Trends in Industrial Vacuum Technology

Looking ahead, several trends will shape the vacuum industry:

Increased IoT Integration: More facilities will connect their vacuum systems to centralized monitoring and analytics platforms.

Higher Efficiency Standards: Expect even stricter energy regulations and certifications.

Greater Customization: Modular systems designed for plug-and-play integration with smart factories.

Focus on Oil-Free Technology: Particularly in pharmaceuticals, food, and semiconductor production.

Predictive Maintenance as Standard: Maintenance scheduling based on real-time performance data.

Atlas Copco continues to lead the charge, investing heavily in R&D to ensure their vacuum solutions are not just ready for the future—but helping to create it.

Conclusion

Industrial vacuum technology has evolved from basic mechanical pumps to highly intelligent, energy-efficient systems capable of transforming manufacturing processes. With innovations like VSD⁺, HEX@™, and GENIUS Instant Insights™, Atlas Copco is at the forefront of this transformation, offering solutions that maximize uptime, reduce operating costs, and support sustainability goals.

This content is proudly provided by Industrial Air Services, your trusted source for Atlas Copco vacuum solutions in Nashville, Knoxville, and Chattanooga. Whether you need a new system, a retrofit, or expert advice, our team is here to help.

📞 Call Industrial Air Services at (615) 641-3100 today for sales, service, or consultation.

A Guide to Griswold's 811 ANSI Series: Features, Benefits, and Applications

In the world of industrial fluid handling, reliability, efficiency, and ease of maintenance are non-negotiable. When choosing a centrifugal pump, especially one designed to meet ANSI B73.1 standards, operators need a solution that can perform under pressure, simplify system design, and minimize long-term costs. That’s where the Griswold 811 ANSI Series shines.

Engineered for tough operating environments and known for its broad range of sizes and materials, the Griswold 811 is a direct competitor to legacy pumps like the Goulds 3196—but with unique advantages in performance, lead time, and serviceability. Whether you’re upgrading your facility, replacing a legacy pump, or building a new system from scratch, the Griswold 811 offers a flexible and economical solution.

In this post, we’ll take a detailed look at the 811 ANSI Series—what sets it apart, how it performs, and why Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga, recommends it to industrial clients across the Southeast.

📞 To get a quote or discuss your pump application, call Industrial Air Services at (615) 641-3100 today.

What Is the Griswold 811 ANSI Series?

The Griswold 811 ANSI Series is a line of horizontal, single-stage, end-suction centrifugal pumps designed to meet ANSI B73.1 dimensional standards. This means they are fully compatible with other ANSI-standard pumps, making them ideal for retrofits and replacements.

The 811 Series is designed to deliver reliable, efficient performance in applications that involve:

Chemical processing

Pulp and paper manufacturing

Wastewater treatment

Food and beverage production

Oil and gas transfer

Water purification and boiler feed systems

Each model is engineered for back pull-out service, which allows maintenance teams to service internal components without disturbing piping—a key time-saver for high-usage facilities.

Key Features of the Griswold 811 ANSI Series

The 811 Series is built with durability, flexibility, and total cost of ownership in mind. Here’s what makes it stand out:

28 casing sizes for high-performance hydraulic coverage

Flow rates up to 7,000 GPM

Heads to 730 feet

Wide range of material options: ductile iron, 316 stainless, Alloy 20, CD4MCu

Open or enclosed impellers based on application

Back pull-out design for easy maintenance

Interchangeable with other ANSI-compliant pump lines

Multiple seal chamber configurations including standard, enlarged, and ISO

Its ability to meet a broad spectrum of flow and pressure requirements makes it a true workhorse in industrial pumping systems.

Advantages Over Competing Pumps

When compared to other ANSI-standard pumps such as the Goulds 3196, the Griswold 811 offers several performance and value-driven benefits.

Simplified hydraulic coverage: Griswold’s 28-size system provides the same flexibility with fewer models to stock

Superior lead times: Faster manufacturing and delivery versus traditional OEMs

Cost efficiency: Lower purchase and replacement part costs

Versatility: Compatible with existing pipe and base configurations

Reduced vibration and increased reliability with properly selected bearing frames and impellers

Additionally, Griswold’s pumps are fully supported by a comprehensive parts and service network, ensuring long-term success for maintenance teams and operators.

Common Applications by Industry

The Griswold 811 ANSI Series is not a one-size-fits-all pump—it’s a customizable system with configurations suitable for some of the toughest industrial settings.

Chemical Processing:

Acid and base transfer

Solvent pumping

Blending and batching operations

Handling corrosive or abrasive media with proper material selection

Pulp and Paper:

White water circulation

Bleach and chemical pumping

Headbox feed

Black liquor handling

Food and Beverage:

CIP (Clean-in-Place) system pumps

Ingredient transfer

Hot water circulation

Sanitary material options available upon request

Water and Wastewater:

Filter backwash

Lift station and digester feed

Clarifier and settling tank return

Sludge and slurry handling

Oil & Gas:

Produced water transfer

Condensate and cooling loops

Petrochemical process support

Explosion-proof motor compatibility

With the right material and configuration, the 811 Series can thrive in nearly any environment requiring dependable, ANSI-compliant centrifugal pumping.

Maintenance Benefits

The Griswold 811 is designed to make maintenance as efficient and straightforward as possible. That includes:

Back pull-out design allows removal of the rotating assembly without disturbing the suction and discharge piping

Interchangeable components simplify inventory and reduce training needs

ANSI dimensions mean easier swap-outs and compatibility with competitor mounting systems

Wear rings and seal options allow for extended service life

Enhanced bearing frames for higher load capacity and longer life expectancy

With minimal special tools required and easily accessible internals, facilities can cut down on both downtime and labor costs.

Real-World Example: Industrial Plant Retrofit in Little Rock

A regional manufacturing plant in Little Rock, Arkansas, needed to replace five legacy centrifugal pumps used in a process water system. The old units required frequent service, parts were no longer stocked, and downtime was affecting throughput.

Industrial Air Services proposed the Griswold 811 ANSI Series with ductile iron casings and 316SS impellers to handle light abrasives and temperature fluctuations. The results:

Full installation completed with zero piping modifications

Efficiency improved by 11% across the system

Maintenance frequency dropped by 40%

All five pumps now share the same spare parts inventory

📞 Want results like this? Call Industrial Air Services at (615) 641-3100 and request a free pump system review.

Integration with the Griswold Interchangeability Tool

Griswold’s free online Interchangeability Tool allows users to match competitor pump models—such as the Goulds 3196—to a Griswold 811 equivalent. This makes it incredibly easy to:

Retrofit existing systems

Replace failing units

Cross-reference parts for quick ordering

Standardize your facility under one pump platform

Industrial Air Services helps maintenance teams use this tool to save time, reduce costs, and avoid compatibility issues.

Why Industrial Air Services Recommends Griswold

As an authorized Griswold distributor and service partner, Industrial Air Services has firsthand experience with the reliability and performance of the 811 ANSI Series. We support customers across Tennessee with:

Pump sizing and selection

Site evaluations and maintenance planning

Parts stocking and emergency service

Turnkey retrofits and installations

Local, knowledgeable support for long-term pump reliability

With offices in Nashville, Knoxville, and Chattanooga, we’re always within reach for fast, expert service.

📞 To speak with a pump expert near you, call Industrial Air Services at (615) 641-3100 today.

Conclusion

If you’re searching for a powerful, flexible, and ANSI-compliant centrifugal pump, the Griswold 811 ANSI Series delivers everything you need and more. With a proven design, strong material options, excellent part availability, and support from Industrial Air Services, it’s the clear choice for long-term operational success.

This blog is proudly provided by Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga. To request a quote, schedule a walkthrough, or get help selecting the right pump, call (615) 641-3100.

Reducing Downtime: The Role of Griswold's Interchangeability Tool in Industrial Operations

In industrial settings, uptime isn’t just a goal—it’s a necessity. From chemical plants and paper mills to water treatment facilities and food processing plants, a single hour of unexpected downtime can cost thousands in lost production, emergency repairs, and labor. One of the most overlooked contributors to unplanned downtime is slow or inaccurate part replacement during pump maintenance. That’s why Griswold’s Interchangeability Tool has become a critical asset for plant managers and maintenance teams aiming to keep their operations running smoothly.

Griswold, a trusted name in ANSI centrifugal pumps, created this easy-to-use tool to help users instantly identify equivalent replacement parts for a wide range of pumps—including those from other major manufacturers. When paired with reliable product support from Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga, the result is a streamlined maintenance process that reduces delays, eliminates guesswork, and boosts operational efficiency.

📞 Need help preventing downtime? Call Industrial Air Services at (615) 641-3100 for expert support and fast access to Griswold parts and pumps.

Downtime: The Hidden Drain on Profitability

The cost of downtime extends beyond lost output. It also includes labor, energy waste, unfulfilled contracts, and reputational damage. According to recent studies:

82% of companies have experienced unplanned downtime over the last three years

The average cost of downtime across all industries is $260,000 per hour

Maintenance delays account for up to 30% of total downtime in many facilities

What often turns a minor issue into a major outage is the inability to quickly source or identify the correct replacement part. That’s where Griswold’s Interchangeability Tool comes into play.

What Is the Griswold Interchangeability Tool?

The Griswold Interchangeability Part Number Lookup Tool is an online resource that allows users to enter pump model numbers or part descriptions from competing brands and instantly retrieve Griswold equivalent part numbers.

It supports:

Goulds 3196

Summit ANSI Series

Peerless and other legacy pump models

ANSI-standard configurations

The tool helps maintenance teams:

Cross-reference competitor models

Reduce time spent searching catalogs or outdated manuals

Confirm compatibility for quick part ordering

Consolidate inventory under the Griswold 811 ANSI Series umbrella

How the Tool Helps Prevent Downtime

1. Speeds Up Emergency Repairs

Instead of waiting on hold with OEM support or flipping through parts catalogs, maintenance teams can quickly find the replacement parts they need and call Industrial Air Services for same-day or next-day delivery.

2. Reduces Inventory Complexity

Facilities often stock hundreds of individual pump parts from multiple OEMs. The Griswold Interchangeability Tool allows them to consolidate those parts under a single platform—simplifying stocking, reordering, and training.

3. Enables Predictive Maintenance

The ability to proactively source parts for upcoming shutdowns or overhauls means fewer surprises and a smoother maintenance schedule. Teams can pre-order replacement kits based on historical wear data and reduce the chance of extended outages.

4. Avoids Costly Ordering Mistakes

Incorrect part orders delay repairs and inflate maintenance costs. Griswold’s tool ensures users get the exact match they need the first time, reducing costly returns and miscommunications.

Real-World Example: Wastewater Treatment Plant in Arkansas

A municipal wastewater facility in Arkansas faced repeated pump seal failures in an aging fleet of Goulds 3196 units. While the pumps were still functional, sourcing OEM parts had become unreliable due to extended lead times and discontinued components. The maintenance team turned to Industrial Air Services for help.

Using the Griswold Interchangeability Tool, Industrial Air Services:

Cross-referenced legacy seal and impeller part numbers

Supplied Griswold 811 ANSI replacement components that dropped in without system changes

Trained plant personnel on using the tool for future part lookups

Established a local parts stocking program based on usage data

Within six months, the facility reported a 60% reduction in unplanned pump-related downtime and a 22% drop in annual maintenance spending.

📞 Want to build a similar program? Call Industrial Air Services at (615) 641-3100 to get started.

Additional Benefits of the Tool

Completely free and available online 24/7

Covers all major ANSI-compliant pump manufacturers

Helps plant engineers evaluate upgrades, not just replacements

Ideal for MRO teams managing multiple facilities

Built to support standardization initiatives across corporate sites

Why Griswold 811 ANSI Pumps?

The Griswold 811 ANSI Series is the most common replacement for Goulds 3196 and similar models. Designed for compatibility and long service life, it features:

Interchangeable dimensions and parts

High-efficiency impeller designs

Corrosion- and wear-resistant material options

Available in 28 casing sizes for maximum coverage

Easily serviceable with standard tools and back pull-out design

When paired with the Interchangeability Tool, the 811 ANSI Series gives users full control over their pumping systems—without being locked into high-cost OEMs or slow service channels.

Why Partner with Industrial Air Services?

Industrial Air Services is more than a distributor—we’re your pump systems partner. Our team works directly with maintenance managers, engineers, and procurement professionals to ensure you have the right equipment and support when you need it most.

We provide:

On-site pump system assessments

Assistance using Griswold’s Interchangeability Tool

Emergency response and fast parts delivery

Local inventory programs

Installation, training, and repair services

With decades of pump experience across multiple industries, we know how to reduce downtime and extend the life of your equipment.

📞 Call (615) 641-3100 to speak with a Griswold expert today.

Conclusion

Downtime is the enemy of efficiency, but with Griswold’s Interchangeability Tool, your maintenance team can fight back. Whether you’re cross-referencing pump components, building a preventive maintenance kit, or converting from legacy equipment to Griswold’s 811 ANSI Series, this tool saves time, reduces errors, and puts your operation back in control.

This blog is proudly provided by Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga. To learn more about how we support industrial facilities with Griswold pumps and parts, call us at (615) 641-3100 today.

The Competitive Edge: Griswold 811 ANSI Series vs. Goulds 3196 – A Comparative Analysis

When it comes to industrial centrifugal pumps, few names are as widely recognized as the Goulds 3196 and the Griswold 811 ANSI Series. Both pump lines are staples in industries such as chemical processing, pulp and paper, food and beverage, and water treatment. However, despite their shared ANSI B73.1 compliance, these pumps differ significantly in cost, ease of maintenance, lead time, and long-term ownership value.

In this blog, we’ll explore a detailed side-by-side comparison between the Goulds 3196 and Griswold 811 ANSI Series. We’ll analyze design, performance, parts availability, and more—so plant managers, engineers, and maintenance professionals can make the most informed decision when it comes to pump replacement or fleet standardization.

This guide is proudly provided by Industrial Air Services, a trusted distributor and service partner for Griswold products, with offices in Nashville, Knoxville, and Chattanooga.

📞 Ready for a side-by-side quote? Call (615) 641-3100 to speak with a pump specialist today.

ANSI Pump Basics: A Quick Refresher

Both the Goulds 3196 and the Griswold 811 ANSI Series conform to ANSI B73.1 dimensional standards. That means they share identical flange-to-flange dimensions and are interchangeable in terms of installation footprint.

ANSI pumps are known for:

Back pull-out design for easy maintenance

Interchangeable dimensions for multi-vendor sourcing

High corrosion resistance options

Applications ranging from aggressive chemical handling to clean water transfer

Because they share these standards, the decision between pump brands often comes down to performance, cost of ownership, and aftermarket support.

Performance and Hydraulic Range

Both the Goulds 3196 and Griswold 811 offer broad hydraulic coverage for medium to high-flow applications.

Goulds 3196:

Flow: Up to 7,000 GPM

Head: Up to 730 ft

41 size selections

Wide range of impeller trim options

Known for application-specific materials (CD4MCu, Alloy 20, etc.)

Griswold 811 ANSI Series:

Flow: Up to 7,000 GPM

Head: Up to 730 ft

28 casing sizes

Optimized hydraulic coverage with high-efficiency options

Broad range of metallurgy including ductile iron, stainless steel, and more

Verdict: In terms of hydraulic range, both pumps perform nearly identically, with the Griswold line offering a simplified range that reduces inventory requirements.

Parts Interchangeability and Maintenance

One of the strongest advantages of the Griswold 811 is its interchangeability with the Goulds 3196. Griswold offers parts and assemblies that directly drop into the 3196 footprint. This simplifies spare parts management and provides more competitive pricing on:

Impellers

Shafts and sleeves

Casings

Bearing housings

Mechanical seal chambers

Griswold also offers a free Interchangeability Tool to help maintenance teams cross-reference existing Goulds models to Griswold equivalents—making the switch fast and seamless.

Lead Time and Availability

In today’s supply chain environment, lead time can be a deal-breaker.

Goulds 3196:

Extended lead times depending on model and materials

Parts may be limited for older models or less common alloys

OEM-only pricing structure

Griswold 811:

Known for faster lead times and factory-assembled kits

Strong domestic manufacturing base

Widespread availability of common parts through Industrial Air Services

Many Industrial Air Services clients have reduced their pump procurement lead time by more than 50% after switching to Griswold.

Pricing and Cost of Ownership

Initial purchase price often favors Griswold, but where it really shines is in total cost of ownership (TCO).

Griswold customers report:

Lower upfront costs by 10–25% compared to Goulds

More affordable replacement parts

Reduced unplanned downtime due to stronger regional support

Simplified inventory through part consolidation

When budgets are tight but uptime is critical, Griswold’s pricing structure gives plants more flexibility without sacrificing performance.

Materials and Application Fit

Both pump lines offer a wide range of material options for chemical resistance and wear resistance.

Goulds 3196: Extensive metallurgy options for custom applications, particularly known for use in corrosive environments.

Griswold 811 ANSI Series: Offers comparable metallurgy including 316 stainless, Alloy 20, and CD4MCu equivalents. In most industrial environments, Griswold’s offerings match or exceed performance expectations at a more accessible price point.

Real-World Example: Food Processing Facility in Mississippi

A food manufacturing facility in Mississippi operated a dozen Goulds 3196 pumps for CIP (clean-in-place) systems and process water transfer. When the time came for major overhauls, costs for OEM parts and labor began to skyrocket.

Industrial Air Services introduced the Griswold 811 ANSI Series as a drop-in replacement. After testing two pumps side-by-side for 90 days, the facility reported:

Lower vibration and noise with Griswold pumps

Identical flow characteristics

17% reduction in total maintenance costs

Full replacement of remaining pumps within 6 months

Today, the facility is fully converted and relies on Industrial Air Services for rapid part delivery, stocking programs, and on-site service.

📞 Want to compare for yourself? Call (615) 641-3100 and ask for a Griswold-to-Goulds crossover report.

Why Choose Griswold 811 ANSI Series?

ANSI dimensional compliance for easy retrofit

Interchangeable with Goulds 3196

Lower cost of ownership

Fewer sizes = simplified inventory

Proven in chemical, municipal, and industrial markets

Supported by Industrial Air Services for service, startup, and parts

Whether you’re maintaining a single pump or managing a fleet of 50+, Griswold offers the flexibility, reliability, and value that industrial operations demand.

Why Industrial Air Services?

As an authorized Griswold distributor, Industrial Air Services offers:

Engineering support and site evaluations

Pump selection and application consulting

Turnkey installation and retrofits

Local inventory and same-day shipping on common parts

24/7 emergency repair and troubleshooting

Our offices in Nashville, Knoxville, and Chattanooga are ready to support your next maintenance or expansion project with industry-leading knowledge and equipment.

📞 For immediate assistance, call (615) 641-3100 today.

Conclusion

The Goulds 3196 has a long-standing reputation, but the Griswold 811 ANSI Series proves that performance, reliability, and value can come in a more cost-effective, readily available package. With full ANSI compliance, unmatched part interchangeability, and strong regional support from Industrial Air Services, the Griswold 811 is the smart alternative for today’s maintenance teams and plant managers.

This blog is proudly provided by Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga. Contact our team at (615) 641-3100 to request a quote or schedule a pump system review.

Mastering Pump Maintenance: How Griswold's Interchangeability Tool Streamlines Part Replacement

Industrial pumps are the lifeblood of manufacturing, chemical processing, water treatment, and countless other critical systems. But like any mechanical component, pumps are subject to wear—and downtime from pump failure can be costly. The key to maximizing uptime and performance lies in proactive pump maintenance and having access to replacement parts when and where you need them.

That’s where Griswold’s Interchangeability Tool comes in. Designed to simplify the pump maintenance process, this online resource allows users to quickly identify compatible replacement parts across a wide range of ANSI pumps—including Griswold’s 811 Series and legacy competitor models like the Goulds 3196.

In this blog, we’ll explore how Griswold’s Interchangeability Tool can revolutionize the way maintenance teams handle pump servicing and replacement. We’ll also highlight how Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga, supports industries in keeping their systems running smoothly with access to Griswold products and expert technical support.

📞 Need help sourcing replacement pump parts? Call Industrial Air Services at (615) 641-3100 today.

The Cost of Poor Pump Maintenance

When pumps go down, operations suffer. A single failure in a chemical plant, paper mill, or food production line can lead to:

Production delays

Equipment damage

Safety hazards

Regulatory violations

Tens of thousands in downtime losses

According to industry studies, the average cost of unplanned equipment downtime ranges from $2,500 to $25,000 per hour depending on the process. And pumps, while rugged, are often a hidden point of failure due to:

Impeller wear

Seal leakage

Bearing failure

Corrosion and erosion

Improper alignment

Regular maintenance is critical—but even the best maintenance team can’t do their job without fast access to accurate part replacements.

Enter the Griswold Interchangeability Tool

Griswold, a PSG Dover brand and manufacturer of ANSI centrifugal pumps, developed an online Interchangeability Part Number Lookup Tool to solve one of the industry’s most persistent headaches: identifying the correct replacement parts for competitor pump models.

✅ Matches competitor pump models to equivalent Griswold 811 ANSI components

✅ Offers part numbers for casings, impellers, sleeves, shafts, seals, and more

✅ Helps identify upgrades or more efficient configurations

✅ Reduces guesswork and time spent searching through catalogs or old manuals

This tool is especially valuable for facilities that operate a mixed fleet of legacy ANSI pumps from various manufacturers.

A Game-Changer for Maintenance Teams

1. Rapid Identification of Replacement Parts

Maintenance technicians can enter a competitor’s pump model and quickly receive a Griswold equivalent—saving hours of cross-referencing part lists or contacting multiple suppliers.

2. Simplified Inventory Management

By consolidating parts under the Griswold 811 ANSI footprint, facilities can reduce their spare parts inventory while improving part availability and compatibility.

3. Increased Maintenance Efficiency

When a pump goes down, there's no time to wait. The tool streamlines the part lookup process so that downtime is minimized and your system gets back online faster.

4. Supports Predictive and Preventive Maintenance

With easy access to part numbers, managers can build preventive maintenance kits or schedule replacements during planned shutdowns—no surprises, no scrambling.

What Is the Griswold 811 ANSI Series?

Griswold’s flagship product—the 811 ANSI Series—is a line of centrifugal pumps designed to be interchangeable with other ANSI-standard pumps like the Goulds 3196. This makes it a favorite for facilities looking to replace outdated or underperforming pumps without overhauling their piping systems.

Flow rates up to 7,000 GPM

Heads to 730 feet

28 different casing sizes

Cast iron, ductile iron, stainless steel, and special alloys available

Open and enclosed impeller designs

Seal chamber options: standard, enlarged, and ISO

Whether you’re dealing with corrosive chemicals, abrasive slurries, or temperature-sensitive fluids, there’s a Griswold pump and part to match.

Case Study: Pulp & Paper Facility in Arkansas

A pulp processing facility in Arkansas was experiencing repeated failures in a fleet of aging Goulds 3196 pumps. Sourcing parts had become difficult due to long lead times and discontinued SKUs. The facility turned to Industrial Air Services for help.

Using the Griswold Interchangeability Tool, Industrial Air Services:

Identified Griswold 811 replacements for the failing pumps

Provided drop-in-compatible impellers and mechanical seals

Delivered parts and installation support within 48 hours

Helped the facility consolidate spares for future use

Result: Downtime was cut by 90%, and the facility has since standardized new installations on the 811 ANSI line.

📞 Want results like this? Call Industrial Air Services at (615) 641-3100.

How to Use the Interchangeability Tool

Visit the Griswold website and navigate to the Interchangeability Part Number Lookup Tool

Enter your existing pump model or part number

Review the Griswold part recommendations

Contact Industrial Air Services for availability, quotes, or technical assistance

It’s a simple 3-minute process that can save your team hours—or even days—of downtime.

Why Choose Industrial Air Services?

At Industrial Air Services, we’re more than just a distributor—we’re your pump system partner. As a proud provider of Griswold pumps and parts, we bring decades of experience to help you streamline operations and keep your facility running at peak performance.

Application support and product selection

On-site evaluations and walk-throughs

Emergency parts delivery

Pump system audits and upgrades

24/7 support for critical systems

📞 Get expert help today by calling (615) 641-3100.

Conclusion

Griswold’s Interchangeability Tool isn’t just convenient—it’s a maintenance game-changer. With fast, accurate access to equivalent ANSI parts, maintenance teams can reduce downtime, improve efficiency, and gain control over pump inventory. When paired with the rugged, reliable performance of the 811 ANSI Series, your operation has the tools it needs to stay ahead.

This blog is proudly provided by Industrial Air Services, with offices in Nashville, Knoxville, and Chattanooga. For help cross-referencing parts or upgrading your pumps, call (615) 641-3100 or reach out to our team today.

Optimizing Industrial Processes with HOMA’s OC Series Chopper Pumps

Handling challenging industrial wastewater is no small task. Whether you're operating a food processing plant, a paper mill, or a municipal pre-treatment facility, managing heavy solids, fibrous debris, grease, and corrosive liquids is a daily battle. Ordinary sewage or non-clog pumps often fail under such demands, leading to costly downtime, equipment failure, and regulatory issues.

This is where HOMA’s OC Series Chopper Pumps excel. Built to tackle the most difficult solids-laden wastewater streams, these pumps deliver exceptional performance, cutting capabilities, and durability for aggressive industrial and municipal applications. Engineered for continuous operation under the harshest conditions, the OC Series is an essential solution for facilities that can't afford clogging or inconsistent flow.

In this article, we’ll take a deep dive into the features and benefits of the HOMA OC Series, explore real-world applications, and show how Industrial Air Services, with locations in Nashville, Knoxville, and Chattanooga, can support your operation with expert system design, installation, and service.

To discuss your wastewater challenges or request a quote, call (615) 641-3100 today.

The Challenges of Industrial Wastewater

Unlike standard municipal sewage, industrial wastewater often contains:

Tough fibrous solids

High grease and fat content

Abrasive slurries

Stringy or plastic materials

Sludge and sediment

Cleaning chemicals and pH variation

These conditions demand more than a pump that simply passes solids. They require a pump that actively chops and handles them without clogging, binding, or breaking down. Chopper pumps are uniquely suited for this task because they combine powerful hydraulics with integrated cutting mechanisms that shred solids before they can do damage.

Overview of the HOMA OC Series

The HOMA OC Series Chopper Pump is purpose-built for heavy-duty applications where reliability and solids reduction are non-negotiable. These submersible pumps feature high-efficiency motors and hardened hydraulic components that are designed to last even in the toughest environments.

Core features include:

Flows up to 1,200 GPM

Heads exceeding 260 feet TDH

High-chrome white iron impellers and cutter systems

Explosion-proof motor options (FM-approved)

Available in submersible and dry pit configurations

Automatic moisture and temperature sensors

Designed for high efficiency and low maintenance

Whether you're upgrading an existing lift station or designing a new process system, the OC Series offers the ruggedness and flexibility your facility needs.

Advanced Cutting System

The OC Series includes an integrated chopping mechanism that reduces large solids and fibrous material into smaller particles before they reach the impeller. This protects the impeller, improves hydraulic performance, and virtually eliminates the risk of clogging.

The cutter system consists of:

A high-chrome steel stationary cutter ring

A rotating cutter mounted behind the impeller

Precision-ground cutting edges hardened for long life

Self-cleaning action that resists jamming and wrapping

This enables the pump to handle:

Rags and stringy materials

Meat and food waste

Sanitary wipes and packaging

Industrial plastic debris

Slaughterhouse runoff

Sludge and process slurry

Durability Under Pressure

Industrial environments often present more than just solids—they introduce chemical corrosion, variable temperatures, and pressure extremes. That’s why HOMA constructs the OC Series with:

High-chrome white iron impellers and volutes for abrasion and corrosion resistance

Ceramic-coated components (optional) for ultra-harsh environments

Double mechanical seals in oil baths for long service life

Motor insulation to Class H with thermal protection

Sealed, pressure-tested motor housings

These features allow OC Series pumps to deliver reliable service in food processing, manufacturing, oil and gas, and chemical wastewater applications.

Performance Without Compromise

HOMA OC Chopper Pumps don’t sacrifice hydraulic efficiency for cutting power. In fact, they deliver:

Hydraulic efficiencies up to 65%

Excellent flow range even under variable loads

Energy-efficient motors with continuous duty ratings

Compatibility with variable frequency drives (VFDs) for adjustable speed control

Smooth, low-vibration operation

This makes the OC Series an excellent long-term investment—providing reduced operating costs while maximizing system uptime.

Flexible Installation Options

OC Series pumps are available in multiple mounting and installation formats, including:

Submersible wet well guide rail setups

Horizontal or vertical dry pit installations

Packaged pumping systems

Retrofit brackets for competitor system compatibility

Jacketed motors for cooling in dry environments

This flexibility ensures the OC Series can be integrated into virtually any system with minimal modifications.

Real-World Example: Meat Processing Plant in Middle Tennessee

A regional meat processing facility contacted Industrial Air Services after multiple failures of standard sewage pumps used to move high-fat wastewater to their on-site treatment plant. Grease, tissue, and cleaning byproducts were clogging their pumps weekly.

They installed two HOMA OC Series Chopper Pumps rated for 150 GPM at 160 feet TDH. Each was installed with stainless-steel guide rail systems, ceramic-coated volutes, and remote moisture/temp monitoring sensors.

Results:

Zero clogging events in the first 18 months of use

Reduced pump room maintenance by 70%

Improved flow and retention time in treatment plant

Facility saved $18,000 annually in labor and replacement costs

To discuss your own high-solids wastewater application, call (615) 641-3100 today.

Explosion-Proof Models for High-Risk Sites

For facilities that handle flammable materials, cleaning agents, or volatile organics, the OC Series is available with FM-approved explosion-proof motors. These are certified for:

Class I, Division 1 hazardous locations

Use in petroleum, chemical, or solvent-based environments

Safe operation even in confined or enclosed pump rooms

Combined with HOMA’s moisture sensors and seal protection features, these pumps are built for critical installations where failure is not an option.

Who Uses HOMA OC Series Pumps?

The OC Series is trusted in industries including:

Meat and poultry processing

Food and beverage production

Agricultural waste and slurry pumping

Pulp and paper

Chemical and petrochemical facilities

Industrial wastewater pretreatment

Municipal headworks and screening stations

Industrial Air Services works with each client to ensure pump selection is optimized for flow, head, solids content, chemical compatibility, and control integration.

Why Choose Industrial Air Services?

We are a leading supplier and service provider for HOMA Pumps across Nashville, Knoxville, and Chattanooga, offering:

System evaluation and site visits

Pump sizing and specification

Installation, controls, and startup support

Preventive maintenance and 24/7 service

OEM parts and fast repair turnaround

We don’t just install equipment—we build long-term relationships based on performance and results.

Call (615) 641-3100 to get started with an OC Series pump or schedule a system review.

Conclusion

In the most demanding wastewater environments, reliability is everything. HOMA’s OC Series Chopper Pumps offer unmatched cutting capability, robust construction, and high-efficiency performance that’s proven in real-world industrial and municipal operations. With built-in protections, flexible mounting, and best-in-class materials, these pumps are ready to tackle whatever solids-heavy wastewater you throw at them.

This blog is proudly provided by Industrial Air Services, your authorized HOMA Pump partner for Nashville, Knoxville, and Chattanooga. Contact us today at (615) 641-3100 to discuss how an OC Series Chopper Pump can solve your toughest wastewater challenge.

Enhancing Sewage Treatment with HOMA's GRP Series Grinder Pumps

Modern sewage systems are facing increasing demands as populations grow, infrastructure ages, and the presence of non-biodegradable solids—like wipes, plastics, and packaging materials—continues to rise. For wastewater systems to operate efficiently, especially in areas with low-flow conditions or long discharge runs, grinder pumps play a critical role. These pumps are designed to reduce solids into fine slurry, preventing clogs and improving flow throughout the system.

Among the top-performing products in this space is the GRP Series from HOMA Pumps. Engineered with robust materials, powerful motor options, and a proprietary cutter system, HOMA’s grinder pumps are trusted in residential, commercial, and light municipal applications. They’re purpose-built to shred the toughest materials and keep sewer lines flowing—even in the most demanding situations.

This blog will explore the advanced features of HOMA’s GRP Series Grinder Pumps, the industries and applications they serve, and how Industrial Air Services—with locations in Nashville, Knoxville, and Chattanooga—can help you install and maintain these high-efficiency systems for long-term success.

To schedule a consultation or service appointment, call (615) 641-3100 today.

The Role of Grinder Pumps in Modern Wastewater Systems

Grinder pumps are designed to process wastewater containing solids by macerating the solids into smaller particles, creating a homogenous slurry that can be easily pumped through small-diameter pipes. This is especially important in:

Low-pressure sewer systems

Remote or rural installations

Basements or below-grade structures

Commercial kitchens and multi-family dwellings

Without a grinder pump, solids can accumulate in the pipes, causing backups, system damage, and costly maintenance issues.

Unlike standard sewage pumps that simply pass solids through, a grinder pump cuts and pulverizes solids before transport, ensuring reliability even in the face of difficult waste streams.

Overview of the HOMA GRP Series Grinder Pumps

The HOMA GRP Series is a line of submersible grinder pumps designed for residential, commercial, and light municipal wastewater applications. What sets these pumps apart is their exceptional ability to shred soft solids and fibrous material while delivering reliable, energy-efficient performance.

Key specifications include:

Motor sizes from 1 to 15 horsepower

Single- and three-phase models

Capacities up to 130 GPM

Heads up to 200 feet

FM-approved explosion-proof versions

Available in wet pit or dry pit installations

Integral level control options

Whether you’re outfitting a new pump station or replacing an older grinder pump, the GRP Series provides dependable performance that reduces the likelihood of clogging and cuts maintenance frequency.

Built-In Cutter System: The Core of the GRP Advantage