Custom Vacuum Systems: How Atlas Copco Engineers Tailor Solutions for Every Industry

When it comes to industrial vacuum systems, a one-size-fits-all approach rarely delivers the best results. Every manufacturing process, plant layout, and operational demand is different. That's why custom vacuum systems have become increasingly important for companies that prioritize energy efficiency, reliability, and production quality.

Atlas Copco has long recognized this need for customization. Their Systems + Solutions engineering group works with businesses across industries to design vacuum systems specifically tailored to each customer’s processes, environment, and goals.

In this blog, we'll dive into why custom vacuum solutions are crucial, how Atlas Copco delivers them, and why Industrial Air Services is your best partner for designing and supporting a system that works for you.

📞 Ready to discuss your custom vacuum needs? Call Industrial Air Services at (615) 641-3100 today. We proudly serve Nashville, Knoxville, and Chattanooga.

The Problem with Off-the-Shelf Vacuum Systems

Prepackaged, off-the-shelf vacuum systems are convenient—but they rarely provide optimal performance.

Common problems with cookie-cutter solutions include

Oversized or undersized systems wasting energy

Insufficient redundancy leading to costly downtime

Space conflicts with existing plant layouts

Poor integration with plant controls (SCADA, PLC)

Failure to meet industry-specific standards for cleanliness or safety

Every facility has unique factors such as operating hours, flow requirements, pressure ranges, environmental conditions, available floor space, and long-term production goals. A poorly matched vacuum system can lead to excessive energy bills, equipment failures, and lost production.

What Is a Custom Vacuum System?

A custom vacuum system is an engineered solution designed specifically around your facility’s needs. This might include

Selecting the best pump technology (dry, oil-sealed, liquid ring)

Sizing the pumps accurately for your flow and pressure needs

Designing a centralized or distributed vacuum system layout

Incorporating redundancy for mission-critical applications

Custom control panels, VFDs, and automation integration

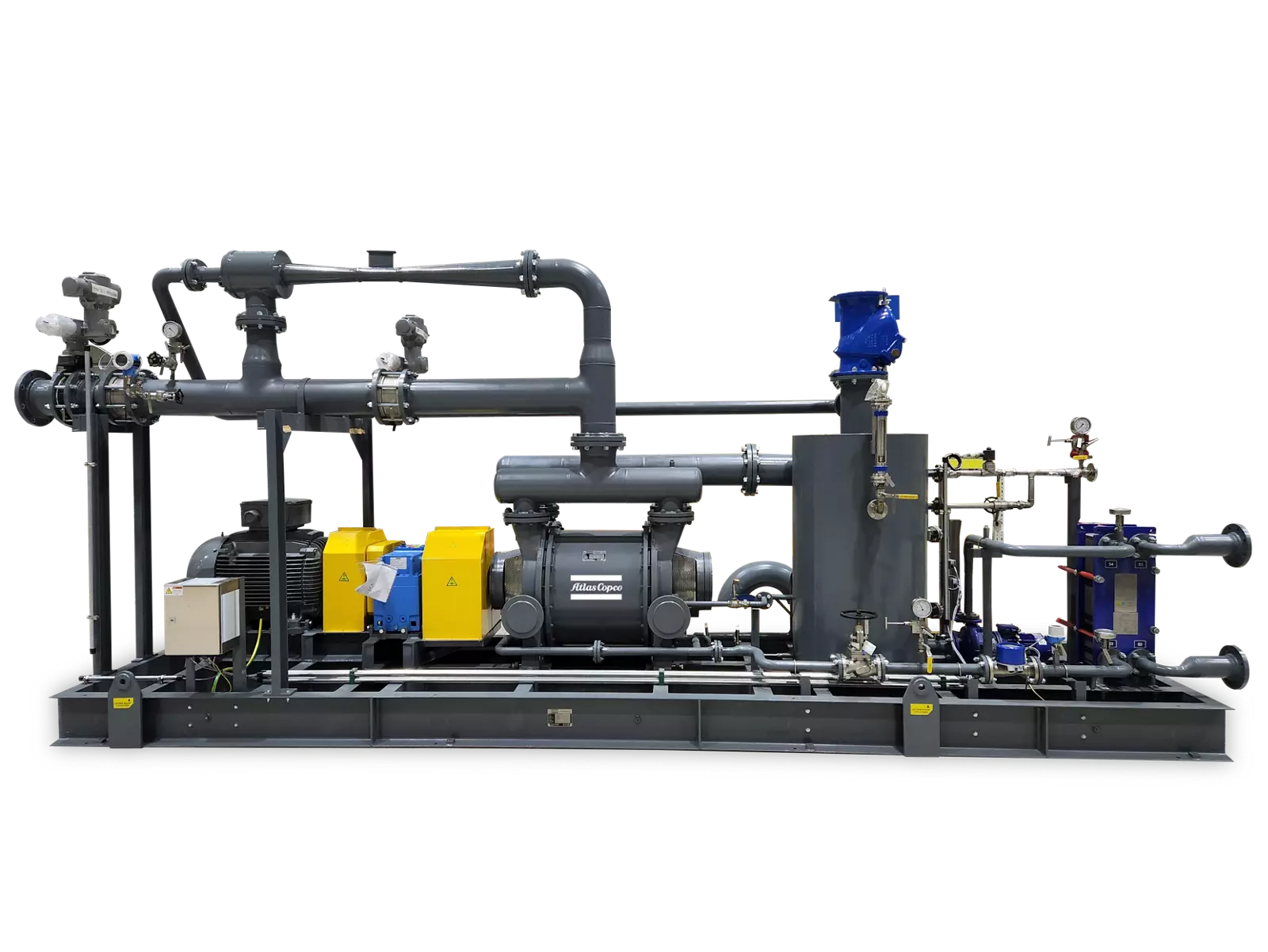

Skid-mounted systems for easy installation

Noise reduction strategies through acoustic enclosures or remote installation

Atlas Copco’s Systems + Solutions team specializes in building these engineered vacuum systems for industries like food and beverage, chemical processing, electronics manufacturing, plastics, energy production, and pharmaceuticals.

Why Atlas Copco Leads in Custom Vacuum Systems

Atlas Copco brings major advantages to custom system engineering, including

Industry-Leading Technology

Atlas Copco’s vacuum pumps include innovations like

VSD⁺ (Variable Speed Drive) for massive energy savings

HEX@™ smart control interfaces

GENIUS Instant Insights™ cloud-based monitoring

Energy recovery options to capture heat for reuse

Whether you need oil-sealed rotary screw pumps, dry screw pumps, claw pumps, or liquid ring technology, Atlas Copco offers best-in-class solutions.

Application-Specific Engineering

Atlas Copco’s engineers don’t just sell products—they analyze your entire vacuum demand curve, production schedule, and layout constraints. They model system performance under real-world conditions to maximize efficiency and reliability.

Energy Optimization

Custom systems are designed to minimize energy waste. Variable speed operation, intelligent pump staging, and real-time load adjustment ensure you use only the energy you need—leading to lower operating costs and a faster ROI.

Scalability and Flexibility

Atlas Copco systems are designed to grow with you. Need to expand production next year? No problem. Custom systems allow for additional pumps or automated load sharing without major redesigns.

Integrated Monitoring and Remote Management

Atlas Copco’s GENIUS Instant Insights™ platform enables 24/7 remote monitoring, predictive maintenance alerts, and real-time system performance reporting—keeping your operation ahead of problems.

Real-World Example: Centralized Vacuum System for a Bottling Plant

A regional beverage manufacturer needed to upgrade their vacuum supply for bottling and packaging lines. Their legacy decentralized system featured multiple small pumps scattered across the facility, causing

High energy costs from inefficient operation

Noise problems on the production floor

Frequent pump failures with no backup redundancy

Industrial Air Services worked with Atlas Copco’s Systems + Solutions team to design a centralized vacuum system featuring

Three GHS VSD⁺ rotary screw vacuum pumps with intelligent load sharing

Custom stainless steel piping network with isolation valves

Remote monitoring and alert system through GENIUS platform

Energy recovery system to capture and reuse waste heat

Results included

38% reduction in total system energy consumption

Noise reduction of 12 dB on the production floor

Zero production downtime from vacuum failures

Payback period of less than two years

📞 Want a customized system assessment? Call Industrial Air Services at (615) 641-3100.

Industries That Benefit from Custom Vacuum Systems

Atlas Copco’s tailored vacuum solutions are trusted across industries like

Food and Beverage Processing (bottling, canning, MAP packaging)

Pharmaceutical and Biotech Manufacturing (sterile transfer, freeze drying)

Plastics and Rubber (extrusion, molding, degassing)

Semiconductor Fabrication (wafer processing, chip manufacturing)

Paper and Pulp Production (sheet forming, dewatering)

Energy and Power (transformer drying, turbine manufacturing)

Every sector has unique vacuum demands, and a custom system ensures that your process operates efficiently and reliably.

Key Components of a Custom Vacuum System

A complete Atlas Copco custom system typically includes

Correctly sized vacuum pumps (dry, oil-sealed, or liquid ring)

Centralized or distributed piping networks

Backup redundancy and isolation valves

Customized PLC or HMI controls with HEX@™ interface

Energy-saving VSD⁺ drives and smart sequencing

Remote monitoring and predictive maintenance features

Optional acoustic enclosures and vibration dampening

By engineering the entire system, not just the pumps, Atlas Copco delivers solutions that are greater than the sum of their parts.

How Industrial Air Services Helps Design Your Custom Solution

At Industrial Air Services, we don’t believe in selling products—we believe in delivering solutions that work.

Our custom vacuum system services include

On-site plant walkthroughs and vacuum demand assessments

System modeling and energy savings calculations

Full engineering design with CAD drawings and performance simulations

Installation, commissioning, and startup support

Preventive maintenance programs to protect your investment

24/7 service and emergency support across Tennessee

From design to implementation, we ensure that your Atlas Copco custom vacuum system is perfectly matched to your needs and fully optimized for performance and reliability.

📞 Ready to explore a custom-designed vacuum solution? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Custom vacuum systems offer unmatched advantages in energy efficiency, process reliability, and long-term operational savings. Atlas Copco’s engineering expertise, paired with Industrial Air Services’ local support, ensures that your facility gets a vacuum system that’s not only effective—but also future-proof.

Industrial Air Services proudly serves the Nashville, Knoxville, and Chattanooga regions as your trusted partner for Atlas Copco vacuum solutions. Contact us today at (615) 641-3100 to schedule a site evaluation or discuss your custom vacuum needs.