The Evolution of Industrial Vacuum Technology: How Atlas Copco Is Leading the Future

Industrial vacuum technology has come a long way from the early days of bulky, inefficient pumps. Today, vacuum systems are the backbone of critical industries like pharmaceuticals, electronics manufacturing, food processing, energy production, and plastics. Modern industrial processes demand vacuum solutions that are energy-efficient, smart, customizable, and sustainable.

At the forefront of this evolution stands Atlas Copco, a global leader known for pioneering innovations that continue to shape the vacuum landscape. In this article, we'll take a closer look at how industrial vacuum technology has evolved—and how Atlas Copco is driving the future with cutting-edge systems like HEX@™, GENIUS Instant Insights™, and Variable Speed Drive (VSD⁺) vacuum pumps.

📞 Need help selecting the right vacuum system for your operation? Call Industrial Air Services at (615) 641-3100 for expert assistance across Nashville, Knoxville, and Chattanooga.

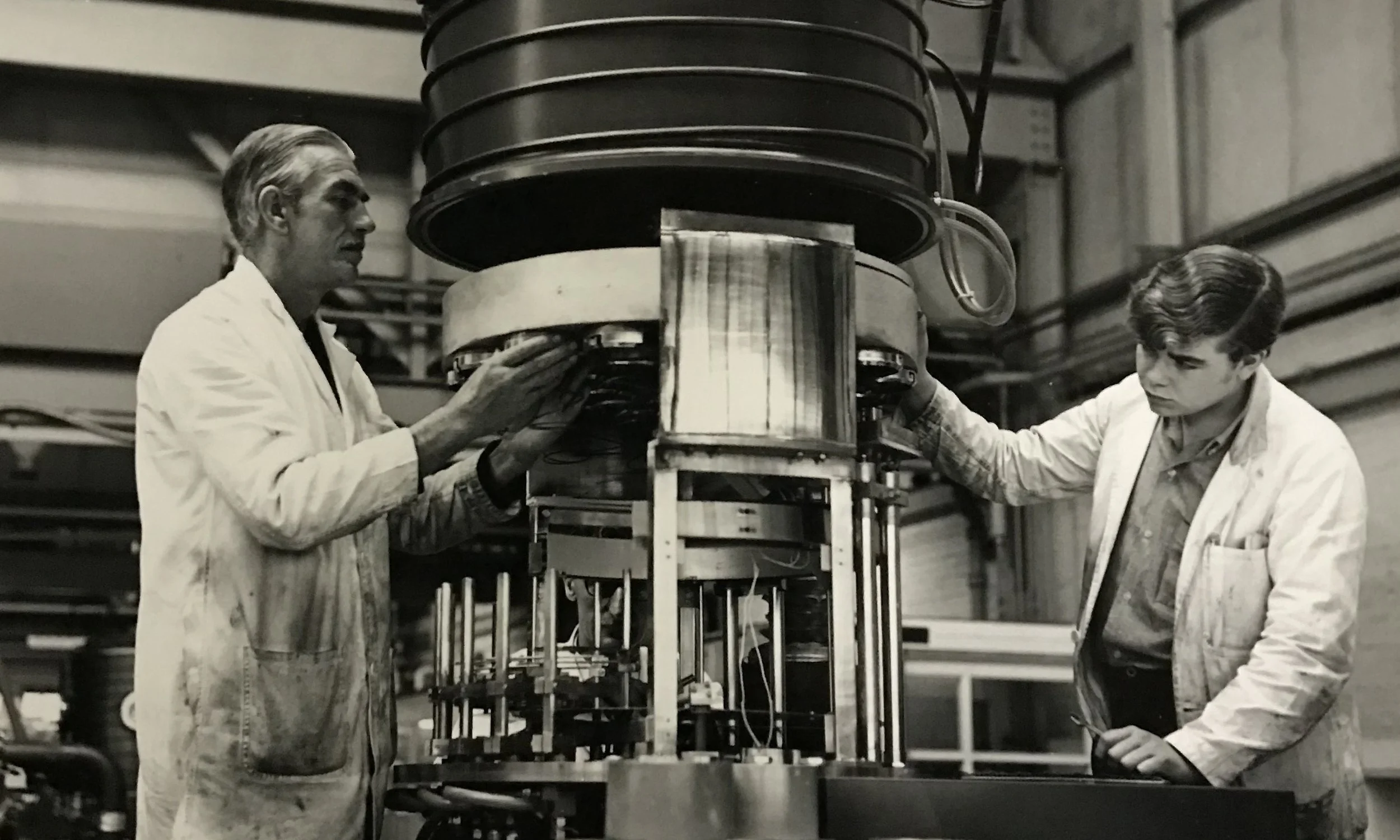

A Brief History of Industrial Vacuum Pumps

Vacuum technology dates back centuries, but industrial applications began in earnest in the 20th century with the rise of mass manufacturing. Early vacuum pumps were primarily oil-sealed rotary vane designs, delivering reliable performance but often requiring significant maintenance and energy.

Key milestones include:

1950s: Introduction of oil-sealed rotary vane pumps for manufacturing.

1970s: Development of dry screw and claw pumps, offering oil-free operation.

1990s: Variable Speed Drive (VSD) technology emerges, improving efficiency in air compressors—and eventually vacuum pumps.

2010s: Connectivity, smart monitoring, and predictive maintenance become available for vacuum systems.

Today, leading manufacturers like Atlas Copco offer sophisticated, application-specific vacuum solutions that maximize efficiency, sustainability, and uptime.

Atlas Copco’s Role in Transforming Vacuum Technology

Atlas Copco’s commitment to innovation has redefined industrial vacuum systems. Let’s explore some key ways they are advancing the industry:

1. Variable Speed Drive (VSD⁺) Vacuum Pumps

Traditionally, vacuum pumps operated at a fixed speed, regardless of the actual demand. This meant wasted energy, frequent cycling, and premature wear.

Atlas Copco’s VSD⁺ technology changed that by allowing the pump’s motor speed to adjust automatically to the process demand. This results in:

Energy savings up to 50%

Reduced maintenance intervals

Lower operating temperatures

Longer equipment life

The GHS VSD⁺ Series of rotary screw vacuum pumps and DWS VSD⁺ Dry Screw Pumps are excellent examples of how variable speed vacuum pumps have revolutionized industries like plastics extrusion, woodworking, bottling, and food packaging.

2. HEX@™: Smart Vacuum Control at Your Fingertips

Efficiency isn’t just about hardware—it’s also about control. Atlas Copco’s HEX@™ platform provides a new generation of human-machine interface for vacuum pumps.

Features include:

Easy access to pump status, performance trends, and diagnostics

Remote monitoring capabilities

Customized control over operating parameters

Integration with plant automation and MES/SCADA systems

With HEX@™, operators can fine-tune vacuum performance to match exact process needs—saving energy and reducing the risk of failure.

3. GENIUS Instant Insights™

Predictive maintenance is the future of industrial reliability, and Atlas Copco leads the way with GENIUS Instant Insights™.

GENIUS is a cloud-based monitoring platform that connects to Atlas Copco vacuum pumps, providing:

Real-time system status

Maintenance reminders and alerts

Energy consumption reports

Early warnings of potential problems

This proactive approach allows facilities to fix small issues before they become big failures, dramatically improving uptime and reducing emergency repair costs.

4. Tailor-Made Systems: Systems + Solutions

Not all facilities have the same vacuum needs. That’s why Atlas Copco offers custom engineering through its Systems + Solutions service.

Custom solutions may include:

Centralized vacuum systems

Redundancy for critical applications

Skid-mounted units for space-constrained environments

Custom PLC integration

These tailored solutions ensure that customers get exactly the performance they need—without over- or under-sizing equipment.

How Vacuum Technology Is Supporting Sustainability Goals

Sustainability is no longer optional—it's a mandate. Modern vacuum systems must align with global efforts to cut carbon emissions and reduce environmental impact.

Atlas Copco’s innovations help companies achieve:

Lower energy consumption: VSD⁺ and intelligent control mean less wasted energy.

Reduced oil and water usage: Dry vacuum pumps eliminate oil contamination and water sealing needs.

Minimized downtime: Predictive maintenance reduces the environmental impact of emergency production shutdowns.

Smaller carbon footprints: More efficient vacuum systems contribute to corporate ESG goals.

By investing in smart, energy-saving vacuum technology, companies can not only save money but also meet growing environmental regulations.

Industry Applications Where Atlas Copco Excels

Atlas Copco’s vacuum solutions serve a wide range of industries, including:

Pharmaceuticals: Cleanroom-compatible dry pumps for sterile production.

Electronics and Semiconductor Manufacturing: Ultra-clean, oil-free vacuum systems critical for chip fabrication.

Food and Beverage: Hygienic vacuum for packaging, filling, and preserving freshness.

Plastics and Rubber: Vacuum forming and extrusion applications.

Power and Energy: Degassing and insulation production for turbines and transformers.

Printing and Packaging: Consistent vacuum for printing presses and flexible packaging machines.

Across each sector, Atlas Copco’s vacuum innovations offer measurable improvements in energy efficiency, reliability, and process quality.

A Look at Key Product Lines

Here are just a few highlights of Atlas Copco’s broad vacuum portfolio:

GHS VSD⁺ Series: Energy-efficient oil-sealed rotary screw vacuum pumps.

DWS VSD⁺ Series: High-performance dry screw vacuum pumps.

LRP VSD⁺ Series: Liquid ring pumps designed for vapor-heavy and wet applications.

DZS Series: Compact dry claw pumps with low noise and high durability.

AWC/AWS/AWL Series: Robust liquid ring vacuum pumps for harsh environments.

No matter the process or environmental conditions, there’s an Atlas Copco vacuum solution to fit.

📞 Need help determining which system is right for your operation? Call Industrial Air Services at (615) 641-3100.

Future Trends in Industrial Vacuum Technology

Looking ahead, several trends will shape the vacuum industry:

Increased IoT Integration: More facilities will connect their vacuum systems to centralized monitoring and analytics platforms.

Higher Efficiency Standards: Expect even stricter energy regulations and certifications.

Greater Customization: Modular systems designed for plug-and-play integration with smart factories.

Focus on Oil-Free Technology: Particularly in pharmaceuticals, food, and semiconductor production.

Predictive Maintenance as Standard: Maintenance scheduling based on real-time performance data.

Atlas Copco continues to lead the charge, investing heavily in R&D to ensure their vacuum solutions are not just ready for the future—but helping to create it.

Conclusion

Industrial vacuum technology has evolved from basic mechanical pumps to highly intelligent, energy-efficient systems capable of transforming manufacturing processes. With innovations like VSD⁺, HEX@™, and GENIUS Instant Insights™, Atlas Copco is at the forefront of this transformation, offering solutions that maximize uptime, reduce operating costs, and support sustainability goals.

This content is proudly provided by Industrial Air Services, your trusted source for Atlas Copco vacuum solutions in Nashville, Knoxville, and Chattanooga. Whether you need a new system, a retrofit, or expert advice, our team is here to help.

📞 Call Industrial Air Services at (615) 641-3100 today for sales, service, or consultation.