How Dekker’s ChemSeal Series Tackles Aggressive Chemical and Corrosive Gas Applications

Provided by Industrial Air Services – Serving Nashville, Knoxville & Chattanooga. Call (615) 641-3100 for sales, installation, or technical support.

In chemical manufacturing, vacuum pumps are exposed to some of the most punishing environments imaginable. From acids and solvents to high-temperature vapors and explosive atmospheres, these systems must perform reliably while handling corrosive and potentially hazardous gas streams.

Standard vacuum pumps can’t survive these conditions. That’s why Dekker Vacuum Technologies developed the ChemSeal Series—a line of liquid ring vacuum pumps engineered specifically for chemically aggressive applications. These systems offer rugged construction, corrosion-resistant materials, and FM-approved options to meet the safety and performance needs of today’s chemical and pharmaceutical processors.

At Industrial Air Services, we help chemical plants across Tennessee design and install ChemSeal systems that can stand up to real-world demands—safely, efficiently, and with confidence.

What Makes Chemical Vacuum So Demanding?

Chemical applications present unique challenges to vacuum systems:

– Corrosive gases and vapors (such as chlorine, HCl, SO₂, acetone, or ammonia) – High temperatures that degrade seals, gaskets, and bearings – Condensable vapors that turn to liquid inside the pump, causing erosion or slugs – Process fluctuations in pressure and load – Explosion risk in volatile or solvent-heavy environments

Any of these issues can cause premature failure in standard pumps, leading to costly downtime, safety risks, and non-compliance with environmental regulations.

The ChemSeal Advantage

Dekker’s ChemSeal liquid ring vacuum pumps are built for the extreme. Using high-grade materials and specialized components, these systems are designed to resist corrosion, control volatile emissions, and operate continuously under harsh conditions.

Core features include:

– Corrosion-resistant construction: Options include 316 stainless steel, Duplex stainless, or other exotic alloys for all wetted components – FM-approved explosion-proof motors: Ideal for Class I, Division 1 environments – Seal liquid containment: Closed-loop operation prevents contaminated discharge and protects personnel – Heavy-duty bearings and shaft seals: Withstand thermal cycling and pressure surges – Gas scrubber compatibility: Seamlessly integrates with vapor recovery or abatement systems – Custom system design: Skid-mounted, tested, and ready for turnkey integration into existing infrastructure

These features make ChemSeal the go-to choice for aggressive process environments where uptime and safety are non-negotiable.

Common ChemSeal Applications

Chemical manufacturing includes a wide range of processes where ChemSeal pumps excel:

– Vacuum distillation and evaporation – Reactor vessel evacuation – Crystallization and solvent stripping – Degassing of resins and polymers – Drying ovens and rotary dryers – Transfer and filtration under vacuum – Environmental remediation involving VOCs or HAPs

ChemSeal pumps are also used in pilot plants, lab-scale systems, and hazardous material containment setups where reliability is paramount.

Real-World Case: Solvent Recovery Line in Middle Tennessee

A specialty chemical plant in Middle Tennessee needed a vacuum solution for its solvent recovery system, which processed highly acidic and flammable vapors at elevated temperatures.

Previous systems had failed due to seal degradation and corrosion of the wetted surfaces. Industrial Air Services collaborated with Dekker to deliver a ChemSeal system built with 316 stainless steel, explosion-proof motor, and a closed-loop seal liquid circuit compatible with the plant’s solvent.

Results:

– Zero unplanned downtime in 18 months – Improved recovery efficiency by 22% – Eliminated corrosion-related service calls – Full compliance with local and federal emission regulations

Material Selection Matters

Not all stainless steel is created equal. Industrial Air Services works closely with Dekker’s engineers to select materials that match your specific chemical exposure:

– 316 Stainless Steel: Excellent general chemical resistance – Duplex Stainless Steel: Higher strength and better chloride resistance – Hastelloy® or Alloy 20: Used for particularly aggressive acid or oxidizer applications – Ceramic Coatings: Optional for added abrasion and pH protection

By selecting the right material for impellers, pump casings, and sealing elements, we ensure your system operates safely and reliably under the full range of process conditions.

Explosion-Proof Options for Hazardous Environments

Many chemical and pharmaceutical plants are classified as hazardous areas due to the presence of flammable vapors or solvents. ChemSeal systems are available with:

– FM-approved motors – Sealed conduit and electrical fittings – Intrinsically safe sensor circuits – Anti-static coatings and corrosion-resistant housings – Motor insulation and thermal protection systems

Industrial Air Services ensures these components are properly selected, installed, and tested for compliance with Class I, Division 1 requirements and NEC/OSHA standards.

Smart Monitoring and Control

ChemSeal vacuum systems can be outfitted with integrated sensors and control panels that monitor:

– Seal liquid level and temperature – Vacuum pressure – Pump motor current – Fluid flow rate – Safety interlocks for vapor recovery or scrubber operation

These features help maintenance teams anticipate problems, optimize performance, and reduce total cost of ownership.

Custom Skid Packages Available

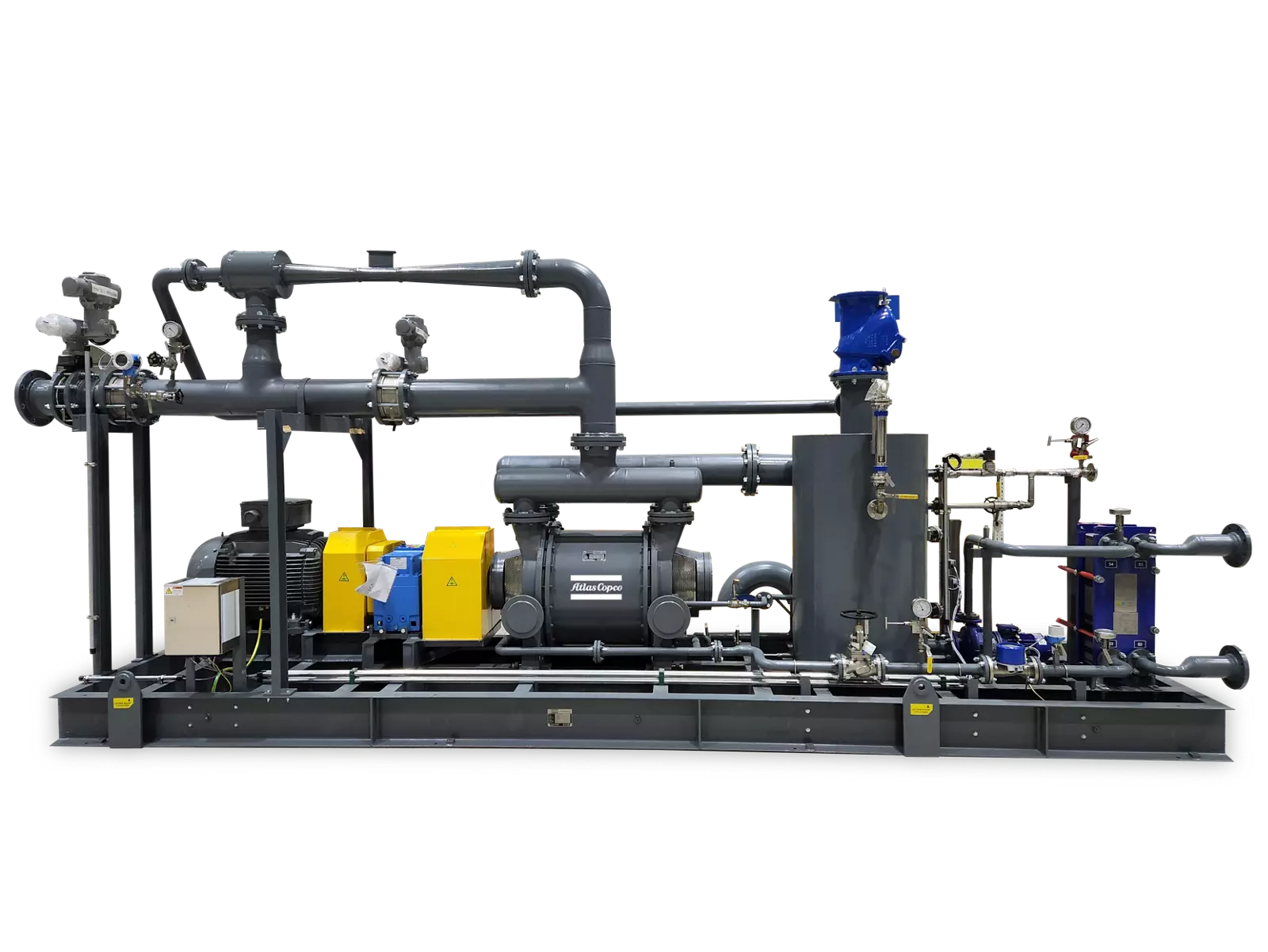

Industrial Air Services can design ChemSeal systems as modular skid packages that include:

– Vacuum pump and motor – Liquid separator and filtration system – Control panel (with optional PLC/SCADA integration) – Explosion-proof junction boxes and conduit – Piping manifolds and valves – Maintenance access zones and drain ports

These systems arrive ready to install and are fully tested at the factory before shipment.

Why Work with Industrial Air Services?

We’re more than a parts supplier—we’re your vacuum system partner. Our team provides:

– Application-specific design support – Dekker-certified startup and commissioning – Preventive maintenance programs – Emergency field service and repairs – Regional inventory of OEM fluids and parts – Dekker factory training and technical support

With offices in Nashville, Knoxville, and Chattanooga, we respond quickly to your needs and understand the specific demands of chemical production facilities across the Southeast.

Conclusion

When your vacuum system faces corrosive, volatile, or chemically reactive gases, you need more than a generic pump—you need a solution that’s engineered for survival. Dekker’s ChemSeal series, combined with the hands-on support of Industrial Air Services, delivers the performance, safety, and longevity that chemical manufacturers require.

Call Industrial Air Services at (615) 641-3100 to request a system evaluation, material compatibility review, or custom ChemSeal system proposal today.

The Future of Vacuum Pump Reliability: Preventive Maintenance and Monitoring Strategies from Dekker

Provided by Industrial Air Services – Your regional Dekker Vacuum partner in Nashville, Knoxville & Chattanooga. Call (615) 641-3100 for service, audits, and preventive maintenance programs.

Vacuum pumps play a mission-critical role in manufacturing processes across food production, chemicals, pharmaceuticals, plastics, pulp and paper, and energy. But unlike high-profile machinery, vacuum systems are often neglected—until they fail. When that happens, downtime is costly, maintenance is reactive, and product quality may suffer.

Dekker Vacuum Technologies is changing that with advanced design, long-life components, and built-in monitoring systems that take the guesswork out of maintenance. By shifting from reactive repairs to predictive strategies, you can extend equipment life, reduce service costs, and ensure uninterrupted vacuum performance.

At Industrial Air Services, we specialize in helping facilities move from old-school maintenance toward future-ready, condition-based care. Let’s look at how Dekker’s vacuum systems are built for reliability—and how you can take advantage of smart maintenance to protect your operations.

Understanding the Risks of Poor Maintenance

Vacuum pump failure rarely happens overnight. It builds over time from a combination of overlooked oil changes, worn components, clogged filters, or overheating. These failures can lead to

Production downtime Increased scrap or quality issues Overloaded motors and elevated energy bills Unscheduled emergency service calls Shortened equipment lifespan

In many cases, these outcomes are preventable with routine inspections, fluid analysis, and early-warning diagnostics.

Dekker’s Built-In Reliability Features

Dekker doesn’t just build high-performance pumps—it builds them to last. Whether you’re running a DuraVane rotary vane unit or a Vmax oil-sealed liquid ring system, reliability is engineered into every design.

Key durability features include Hardened stainless-steel components in critical wear areas Precision-machined tolerances for reduced internal friction Closed-loop seal fluid systems that reduce contamination and scaling Heavy-duty bearings and shaft seals Low-maintenance oil filtration and recovery systems

These designs reduce the wear rate over time—but like any machine, they still require care to deliver their full lifespan.

Smart Monitoring Systems

Modern Dekker systems offer smart sensor technology, either integrated at the factory or added through Industrial Air Services. Features include

Temperature sensors for motor and seal protection Vacuum pressure sensors for performance tracking Oil level and oil temperature sensors Motor load feedback Leak detection

With these tools in place, you can receive early alerts when parameters drift out of spec—allowing your team to schedule service before damage occurs.

How Preventive Maintenance Saves Time and Money

Preventive maintenance (PM) programs include scheduled inspections, fluid replacements, filter changes, and performance checks at regular intervals based on hours or usage.

The benefits include Reduced risk of catastrophic failure Predictable maintenance budgeting Less downtime from emergency shutdowns Extended pump service life (often by 2–3x) Improved energy efficiency

For example, a properly maintained Vmax system can operate for over 20,000 hours between major overhauls. That’s years of operation with minimal intervention—if routine tasks are handled correctly.

Oil Analysis and Seal Fluid Monitoring

Dekker and Industrial Air Services offer routine oil analysis as part of PM programs. By testing for wear metals, contamination, and viscosity changes, you can catch early signs of

Bearing failure Seal degradation Overheating or cavitation Fluid breakdown due to process gases

We recommend testing at least once every 2,000–4,000 hours depending on pump type and application. This small investment can prevent thousands in repair or replacement costs.

Custom Maintenance Plans from Industrial Air Services

We offer preventive maintenance programs tailored to your equipment and usage. These plans can include

Quarterly, semi-annual, or annual service intervals Dekker-certified oil, filters, and parts On-site vibration and noise diagnostics GENIUS Instant Insights™ remote monitoring setup Maintenance logs and documentation for audits

These plans are ideal for facilities with limited in-house maintenance resources or teams managing multiple plant systems.

Real-World Example: Pharmaceutical Facility in Knoxville

A pharma production site in Knoxville relied on Dekker rotary vane pumps for vacuum drying and tablet coating. They had no formal maintenance schedule—only reacted when pump pressure dropped or strange noises occurred. Industrial Air Services implemented a PM plan that included

Quarterly oil changes and vane checks Biannual motor and bearing inspections GENIUS monitoring alerts for pressure spikes

The result was a 100% reduction in unplanned vacuum downtime and improved product consistency. The pumps also used 12% less energy due to optimized motor loading and airflow management.

GENIUS Instant Insights™: Remote Monitoring for the Win

Dekker’s GENIUS Instant Insights™ platform gives you a remote dashboard for your vacuum system, delivering

Live operating metrics Maintenance reminders System health reports Access from any web-enabled device

Industrial Air Services can install GENIUS hardware, train your staff, and connect the system to your maintenance platform. This tool transforms your vacuum system from a blind spot into a data-rich asset you can manage in real time.

Why Partner with Industrial Air Services

As a regional Dekker distributor and service partner, we offer

Certified Dekker PM programs for all pump types Emergency repair and diagnostic services System rebuilds and upgrade consultation In-stock filters, fluids, and OEM parts Field service across Nashville, Knoxville, and Chattanooga

When you work with us, you get peace of mind that your vacuum systems are operating efficiently—and backed by experts who know the technology inside and out.

Conclusion

Vacuum pump failure doesn’t have to be part of your operating reality. With smart monitoring and preventive maintenance, you can stay ahead of problems, reduce unplanned downtime, and extend the life of your Dekker system.

Dekker’s rugged engineering, combined with Industrial Air Services’ field support, makes it easy to keep your vacuum systems running at peak reliability for years to come.

Call Industrial Air Services at (615) 641-3100 to enroll in a maintenance plan or schedule a no-cost system review today.

Vacuum in Action: How Dekker Supports Mission-Critical Applications in Pulp & Paper, Plastics, and Chemical Processing

Brought to you by Industrial Air Services – Trusted Dekker Vacuum Partner in Nashville, Knoxville & Chattanooga. Call (615) 641-3100 for expert support and custom solutions.

In industrial manufacturing, vacuum systems don’t just support production—they drive it. From removing water in pulp & paper mills to degassing plastics and recovering solvents in chemical plants, reliable vacuum is the heartbeat of efficiency and uptime. When these systems fail or underperform, the ripple effects can disrupt entire operations.

That’s why more facilities are turning to Dekker Vacuum Technologies—a brand known for rugged reliability, engineering precision, and tailored system design. Through its comprehensive product range and commitment to custom solutions, Dekker plays a critical role in some of the most demanding industries in the world.

As a certified Dekker partner, Industrial Air Services delivers local service and application support across Tennessee. Let’s explore how Dekker vacuum systems support mission-critical operations in pulp & paper, plastics, and chemical processing.

Pulp & Paper: Dewatering, Press Support & Couch Roll Efficiency

In pulp and paper manufacturing, vacuum is essential from sheet formation through drying. Whether in the forming section or press section, vacuum systems remove water, support fiber transfer, and reduce energy load downstream.

Common vacuum applications in pulp & paper include:

Couch roll dewatering

Suction box operation

Felt conditioning

Vacuum press support

Transfer roll and turning suction

Challenges in this environment:

Large flow volumes (often thousands of CFM)

Saturated, dirty gas streams

Continuous duty cycles

System sensitivity to pressure fluctuations

Dekker’s solution: Dekker’s Maxima and Vmax series liquid ring vacuum pumps are ideal for this rugged, 24/7 environment. They are engineered to handle large water vapor loads without overheating or fouling and are available in stainless steel or special alloy options for corrosive pulp liquors.

Industrial Air Services helps paper facilities size and design these systems for multiple paper machine sections—offering energy optimization, noise control, and preventive maintenance programs that maximize uptime.

Plastics: Degassing, Thermoforming & Extrusion Support

The plastics industry relies on vacuum for product quality and process efficiency. Whether you’re extruding PVC pipe, vacuum-forming packaging trays, or removing air bubbles during molding, a consistent vacuum level can mean the difference between scrap and sellable goods.

Common vacuum uses in plastics processing:

Extruder venting and degassing

Sheet and film thermoforming

Injection molding support

Resin drying and conveying

Process challenges include:

Varying vacuum demand throughout production

Dust and vapor contamination

Tight tolerances on vacuum level to prevent part defects

Footprint limitations on OEM machinery

Dekker’s solution: The DuraVane rotary vane series is a go-to choice for plastics OEMs and processors, offering compact size, consistent vacuum levels, and simple maintenance. For higher vapor loads or continuous-duty extrusion lines, Dekker’s Vmax oil-sealed liquid ring systems offer a rugged, closed-loop solution that handles sticky gas streams and minimizes fluid consumption.

Case example: A plastics packaging facility near Chattanooga installed a multi-pump Vmax system sized by Industrial Air Services. The upgrade replaced noisy, failure-prone rotary vane pumps and resulted in:

22% reduction in cycle time

Lower scrap rates

30% maintenance cost reduction

Quieter, safer working conditions

Chemical Processing: Solvent Recovery, Distillation & Reactor Evacuation

In the chemical industry, vacuum is indispensable. It enables low-temperature distillation, improves reaction rates, protects sensitive compounds, and recovers valuable solvents. At the same time, these processes often involve corrosive vapors, pressure fluctuations, and safety-critical operations.

Key vacuum applications in chemical plants:

Vacuum distillation

Reactor vessel evacuation

Solvent stripping and recovery

Drying ovens and tray dryers

Filtration and crystallization

Industry challenges include:

Corrosive gases and solvents (acids, alcohols, aromatics)

Fluctuating load conditions

Strict environmental and safety regulations

The need for explosion-proof and FM-approved equipment

Dekker’s solution: The ChemSeal series of liquid ring pumps is purpose-built for corrosive chemical environments. Featuring duplex stainless steel or other exotic alloys, ChemSeal systems offer FM explosion-proof motors and gas-sealing features to handle the harshest gas streams safely and efficiently.

Industrial Air Services provides system audits and can design custom ChemSeal skid packages with:

Solvent-compatible materials

Closed-loop seal liquid recovery

Corrosion-resistant piping and valves

Integrated controls and safety interlocks

Real-world results: A specialty chemical processor in Nashville switched to a ChemSeal system with PLC control and dual pump redundancy. Benefits included:

24/7 uptime with no operator intervention

40% solvent recovery rate improvement

Immediate ROI in under 14 months

Zero safety or environmental compliance violations

📞 Need a vacuum system that works as hard as your process? Call Industrial Air Services at (615) 641-3100 today to get started.

Why Industrial Air Services and Dekker?

Dekker is one of the few vacuum pump manufacturers that offers both product and process engineering. Every pump is backed by decades of industrial experience, with solutions that span:

Liquid ring (Maxima, Vmax, ChemSeal)

Rotary vane (DuraVane)

Rotary piston and hybrid systems

Custom skids and multi-pump systems

Controls, tanks, reservoirs, and separators

Industrial Air Services enhances this offering with:

Local vacuum audits and sizing

Full installation and startup

SCADA and control panel integration

Maintenance, training, and 24/7 emergency response

OEM parts and Dekker-certified service

Whether you need a single-point replacement or a full vacuum system overhaul, we’ll help you plan, install, and support it every step of the way.

Conclusion

In pulp & paper, plastics, and chemical processing, the right vacuum system is the difference between smooth production and costly delays. Dekker’s proven pump technologies—paired with Industrial Air Services’ expertise—deliver custom-engineered solutions that are built for uptime, efficiency, and process stability.

Don’t settle for a generic vacuum system. Partner with Industrial Air Services and get a vacuum solution designed around your process.

📞 Call (615) 641-3100 to schedule a site visit, application review, or request a system proposal today.

Custom Vacuum System Engineering: Inside Dekker’s Turnkey Design Process

Provided by Industrial Air Services – Your Dekker Vacuum Partner in Nashville, Knoxville & Chattanooga. Call (615) 641-3100 for design, installation, and support.

In industrial environments, vacuum systems are often the invisible backbone of production—quietly supporting everything from product handling and packaging to distillation, drying, and chemical recovery. But no two processes are exactly the same. That’s why off-the-shelf vacuum pumps, while convenient, often fall short when it comes to meeting the complex demands of modern manufacturing.

Dekker Vacuum Technologies has earned a reputation for doing things differently. Through its custom vacuum system engineering services, Dekker delivers fully integrated, performance-optimized solutions tailored to each customer’s unique process. Whether your facility is launching a new line or replacing legacy equipment, a custom-designed system ensures reliability, energy efficiency, and scalability.

As the authorized Dekker representative in Tennessee, Industrial Air Services is proud to provide custom vacuum system consultation, installation, and support across Nashville, Knoxville, and Chattanooga.

Let’s explore what makes Dekker’s custom vacuum engineering process exceptional—and how you can benefit from a solution that’s truly built around you.

Why Custom Engineering Matters

Many industrial facilities struggle with vacuum systems that were never quite right from the start—systems that are too large, too small, too complex, or simply not robust enough to meet process demands. These mismatches lead to:

Energy waste from oversized pumps

Excess maintenance from improper materials or poor filtration

Inconsistent vacuum levels, affecting product quality

System failures that create downtime and lost production

Limited ability to scale as needs change

Custom-engineered vacuum systems solve these problems at the root, using real process data and advanced modeling to design a system that’s right-sized, process-matched, and future-proof.

Step-by-Step: Dekker’s Turnkey Vacuum System Design Process

Here’s how Dekker—and Industrial Air Services—turn your vacuum challenges into streamlined, high-performance solutions:

1. Process Assessment

It all begins with a detailed application review. Industrial Air Services engineers will evaluate:

Gas composition and temperature

Vapor load and moisture content

Required flow rate (CFM) and vacuum pressure

Duty cycle and system run times

Environmental and space constraints

Cleanliness and regulatory requirements

We also conduct vacuum audits and collect real-time system performance data when needed.

2. Sizing and Technology Selection

Next, we match your requirements with the right vacuum technology. Dekker offers:

Liquid ring pumps (including the oil-sealed Vmax line)

Rotary vane systems (DuraVane)

Rotary piston and hybrid designs

Custom multi-pump skids and central vacuum systems

The goal is to select the most efficient and reliable option—not just for today, but for years to come.

3. System Layout and 3D Modeling

Dekker’s engineering team creates detailed 3D renderings of your custom vacuum package, including:

Pump, separator, and reservoir positioning

Electrical panel integration

Frame or skid mount design

Maintenance access zones

Sound enclosures or noise abatement

Custom piping or discharge routing

This step ensures a clean installation with minimal surprises, even in tight plant layouts.

4. Controls and Automation

Custom vacuum systems include control panels with relay logic, PLC, or touchscreen options. Dekker can integrate:

Pressure sensors and alarms

Variable speed drive (VFD) controls

Remote monitoring via GENIUS Instant Insights™

SCADA system compatibility

Redundancy sequencing for multi-pump operation

Industrial Air Services will help you program and test these systems on-site.

5. Factory Testing and Commissioning

Every Dekker custom system is fully assembled and tested at the factory in Michigan prior to shipping. You receive:

Verified performance data

FAT documentation

Maintenance guides

Panel wiring diagrams

Easy startup procedures

Upon arrival, Industrial Air Services installs, commissions, and verifies the system at your facility.

📞 Ready for a custom vacuum system designed around your process? Call Industrial Air Services at (615) 641-3100 today.

Applications That Benefit Most from Custom Vacuum Design

Custom systems are ideal for any process with tight tolerances, unique gas loads, or specialized performance demands, including:

Pharmaceutical and biotech: freeze-drying, sterile transfer, solvent recovery

Food and beverage: MAP packaging, dairy processing, vacuum cooling

Chemical manufacturing: distillation, crystallization, vapor recovery

Pulp and paper: couch rolls, dewatering, press section support

Plastic and rubber: extrusion, thermoforming, degassing

Energy and power plants: condenser evacuation, transformer drying

No matter your industry, Dekker and Industrial Air Services can tailor a vacuum solution to fit your exact needs.

Real-World Case Study: OEM Integration in Memphis

A large OEM in Memphis needed a space-saving, plug-and-play vacuum solution for its new automated packaging equipment line. The customer had limited floor space and strict performance requirements for vacuum drawdown and reliability.

Industrial Air Services and Dekker collaborated to design a compact, skid-mounted central vacuum system using DuraVane rotary vane pumps with pre-filtering, reservoir tank, and custom PLC controls.

Results:

Installed in under one day

Integrated seamlessly with customer’s automation logic

Delivered 30% energy savings vs. legacy pump setup

Reduced unplanned maintenance to near-zero

This turnkey solution allowed the OEM to focus on production—not vacuum troubleshooting.

Advantages of a Dekker Custom Vacuum System

Tailored to your exact process requirements

Single-source responsibility: design, components, controls, and documentation

Engineered for future scalability

Pre-tested and ready to run

Local service and support from Industrial Air Services

Reduced TCO (Total Cost of Ownership) from smarter sizing and lower maintenance

Why Work with Industrial Air Services?

As your Dekker-certified regional partner, Industrial Air Services delivers:

Full project management, from design through installation

Application engineering with real-world field experience

Installation by trained, experienced vacuum technicians

Preventive maintenance programs and emergency service

Stocked replacement parts and factory-trained support

Offices serving Nashville, Knoxville, and Chattanooga

You’re not just buying equipment—you’re gaining a team that will support your system for its full life cycle.

📞 Contact Industrial Air Services at (615) 641-3100 today to schedule a vacuum audit or discuss your next custom-engineered solution.

Conclusion

When performance, efficiency, and reliability matter, an off-the-shelf vacuum pump often isn’t enough. Dekker’s custom vacuum system engineering—delivered locally by Industrial Air Services—ensures that every pump, pipe, panel, and parameter is tuned to your exact needs.

If you’re ready to upgrade your vacuum system the right way, call (615) 641-3100 or connect with Industrial Air Services for a consultation today.

How Dekker’s Vmax Systems Revolutionize Liquid Ring Vacuum Pump Efficiency

Provided by Industrial Air Services – proudly serving Nashville, Knoxville, and Chattanooga. Call (615) 641-3100 for sales, service, or consultation.

In industrial vacuum systems, reliability and performance are non-negotiable. Yet, efficiency and sustainability are becoming just as critical as uptime. Whether you're managing a food packaging line, chemical process, or a power plant condenser, your vacuum equipment needs to do more than just “work”—it needs to save energy, reduce waste, and minimize maintenance. That’s where the Dekker Vmax liquid ring vacuum system stands apart.

Dekker has taken the traditional liquid ring pump design and reengineered it for modern industrial demands. The result is a closed-loop, oil-sealed vacuum solution that offers better performance, lower operational costs, and longer equipment life. As an authorized Dekker partner, Industrial Air Services is proud to bring this powerful system to facilities across Tennessee and the Southeast.

Let’s take a closer look at how the Vmax system works, what makes it unique, and why it may be the smartest upgrade you can make to your vacuum infrastructure.

What Is the Vmax System?

The Vmax is a pre-engineered, turnkey vacuum system built around Dekker’s time-tested liquid ring technology. Unlike traditional water-sealed pumps, the Vmax system uses oil as the sealant fluid—allowing for better lubricity, improved vacuum performance, and a fully closed-loop design.

Each Vmax unit includes:

A liquid ring vacuum pump with robust construction

Oil recovery and filtration components

A recirculation reservoir

Inlet filters, discharge separators, and non-return valves

Controls and sensors for real-time operation and monitoring

Everything is skid-mounted and factory-tested, meaning your installation time is minimized, and your system is up and running faster.

Why Oil Sealing Matters

One of the key innovations in the Vmax system is its use of oil instead of water as the sealing liquid. This change offers several critical benefits:

Oil doesn't evaporate easily, reducing make-up fluid costs and maintenance

It provides superior lubrication, lowering friction and wear inside the pump

It enables tighter tolerances, which allow for deeper vacuum levels

It resists corrosion and contamination, even in demanding chemical or vapor-heavy applications

The result? Better performance, longer pump life, and lower total cost of ownership.

Closed-Loop Efficiency

In traditional open-loop liquid ring systems, water is constantly introduced, consumed, and discharged—wasting both fluid and energy. The Vmax system changes that with its closed-loop design, where the oil is continuously filtered and reused.

This creates several distinct advantages:

Near-zero fluid loss, even during continuous operation

Lower utility costs, as there’s no need for fresh water or wastewater treatment

Minimal environmental impact, making it easier to meet sustainability and compliance goals

Combined with energy-efficient motor options and intelligent system controls, the Vmax is a powerhouse of industrial vacuum performance with an impressively low environmental footprint.

📞 To schedule a system review or request a quote, call Industrial Air Services at (615) 641-3100.

Designed for the Real World

Dekker designed the Vmax for plants that need serious vacuum power under rugged conditions. Whether you’re evacuating large tanks, handling saturated vapors, or supporting a multi-line packaging process, the Vmax delivers steady vacuum levels with minimal operator input.

It’s ideal for:

Food and beverage processing

Pharmaceutical and chemical manufacturing

Power plants and refineries

Pulp and paper

General industrial operations

The system is available in a range of sizes and configurations, with vacuum capacities from 35 to over 2,000 CFM. Industrial Air Services can help size and customize your Vmax system to meet your specific production requirements.

Real-World Example: Chemical Plant in Knoxville, TN

A specialty chemical facility in Knoxville was struggling with high maintenance costs and inconsistent performance from its aging water-sealed vacuum pumps. Excess water usage, pump cavitation, and fouling led to frequent downtime—and rising environmental compliance issues due to wastewater disposal.

They installed a Dekker Vmax system with stainless-steel wetted parts and upgraded oil filtration. The results were immediate:

Energy savings of 28%

Zero unplanned downtime in 12 months

No wastewater generation

Return on investment in under 18 months

The plant also reported smoother process control due to consistent vacuum levels and faster cycle times on batch reactors.

Integrated Controls and Diagnostics

Vmax systems come equipped with a control panel and optional PLC integration that makes operation and monitoring simple. Industrial Air Services can help connect your Vmax system to plant SCADA or building automation platforms, allowing:

Remote monitoring

Trend tracking

Automatic alarms for fluid levels, temperature, and vacuum setpoints

Predictive maintenance alerts

This digital capability ensures that maintenance teams can take proactive action—long before problems cause downtime.

Why Choose Vmax Over Traditional Liquid Ring Systems?

Here’s what sets the Vmax apart:

Oil-sealed design extends pump life and improves performance

Closed-loop operation eliminates fluid loss and wastewater

Pre-engineered skid package reduces installation time and risk

Proven durability, even in vapor-heavy or corrosive applications

Lower operating costs across energy, fluid, and maintenance

Full-service support through Industrial Air Services

If your facility is running outdated, water-sealed liquid ring pumps or operating rotary vane pumps that can’t handle the process vapors, it’s time to consider an upgrade.

What You Get with Industrial Air Services

As a Dekker-authorized distributor, Industrial Air Services provides full-cycle support, including:

Application and sizing assistance

Turnkey installation and commissioning

Integration with existing vacuum headers and control systems

Preventive maintenance programs

OEM spare parts and service kits

24/7 emergency response

We’ve helped companies across Nashville, Knoxville, and Chattanooga modernize their vacuum infrastructure—saving money, reducing downtime, and improving process reliability.

📞 Contact Industrial Air Services at (615) 641-3100 today to schedule a site evaluation or demo of the Vmax system.

Conclusion

In industries where reliability and cleanliness matter, the Dekker Vmax liquid ring vacuum system delivers unmatched efficiency, sustainability, and value. With a rugged oil-sealed design and closed-loop operation, it’s built to handle the toughest applications while reducing total cost of ownership. Backed by the regional expertise and 24/7 support of Industrial Air Services, you can rest assured your vacuum system will work just as hard as you do.

Call (615) 641-3100 or visit us to learn more about Vmax systems or request a custom proposal today.

Liquid Ring vs. Rotary Vane: Choosing the Right Vacuum Technology for Your Industrial Process

In the world of industrial vacuum systems, one size does not fit all. Selecting the wrong type of vacuum pump can result in higher energy bills, more frequent maintenance, and reduced productivity. Two of the most popular—and very different—vacuum pump technologies in use today are liquid ring and rotary vane vacuum pumps. Both have proven track records in a wide range of industries, but each brings its own strengths, limitations, and ideal use cases.

Dekker Vacuum Technologies, a leading manufacturer of engineered vacuum solutions, offers high-performance options in both categories, including the Vmax series of liquid ring pumps and the DuraVane series of rotary vane pumps. As an authorized Dekker partner, Industrial Air Services provides expert consultation, installation, and service across Tennessee and the Southeast to help you make the right choice for your application.

📞 To request a site visit or speak with a vacuum expert, call Industrial Air Services at (615) 641-3100 today.

Understanding Liquid Ring Vacuum Pumps

A liquid ring vacuum pump uses a rotating impeller and a sealing liquid—usually water or oil—to generate vacuum. As the impeller turns inside an offset casing, the liquid forms a ring that traps and compresses air between the blades. These pumps are ideal for saturated gas streams and are known for durability in harsh environments.

Dekker’s Vmax series, available through Industrial Air Services, is a top-tier option for industrial facilities that require continuous duty vacuum and efficient operation in wet or contaminated gas streams. The system includes integrated oil recovery, filtration, and control components to reduce waste and simplify maintenance.

Liquid Ring Pump Highlights:

Excellent for handling water vapor, solvents, and particulates

Ideal for food processing, chemical applications, and power generation

Low-maintenance and long-lasting

Quiet, vibration-free operation

Understanding Rotary Vane Vacuum Pumps

Rotary vane pumps operate with a rotor mounted off-center inside a chamber. Sliding vanes trap and compress gas in segmented chambers. These oil-lubricated pumps provide high vacuum levels and are ideal for clean, dry applications that require steady mid-to-deep vacuum.

Dekker’s DuraVane series, distributed and serviced by Industrial Air Services, offers precision-machined, compact rotary vane systems that are popular for packaging, printing, woodworking, and medical suction systems.

Rotary Vane Pump Highlights:

Compact and efficient for intermittent use

Simple to service with regular oil changes

Effective for dry, clean gas streams

Fast startup and deep vacuum levels

Key Differences: Which Is Right for You?

Vacuum level needs: Rotary vane pumps generally offer deeper vacuum than liquid ring systems and are ideal when pressures below 25 Torr are required.

Gas composition: Liquid ring pumps handle vapors, moisture, and contaminants with ease, while rotary vane systems require dry intake gas.

Maintenance and lifecycle costs: Liquid ring pumps require less frequent attention, while rotary vane pumps need routine oil changes and vane inspections but may offer greater energy efficiency for light-duty use.

Continuous operation: For round-the-clock vacuum needs, especially in humid or dirty environments, liquid ring pumps like the Vmax are ideal. Rotary vane pumps excel in batch or cycling processes.

System footprint and complexity: Rotary vane systems are compact and straightforward. Liquid ring systems may require additional fluid handling and separators, but offer superior durability.

Real-World Example: Food Packaging Application

A major Tennessee-based food packaging plant turned to Industrial Air Services when it needed to upgrade its aging vacuum system used for MAP (Modified Atmosphere Packaging). The facility’s process produced moisture and residue that clogged and degraded the performance of its previous rotary systems.

A Dekker Vmax liquid ring system was installed for its ability to handle moisture-laden gas streams with zero performance loss. The new system improved uptime, reduced energy costs by 20%, and eliminated unplanned maintenance events over a 12-month span.

Hybrid Solutions? Dekker Can Do That Too

Sometimes, the best solution is a hybrid approach. Dekker and Industrial Air Services can engineer vacuum systems that combine the energy savings of rotary vane pumps with the moisture tolerance of liquid ring pumps. We provide tailored, turnkey packages that balance cost, performance, and long-term ROI.

Why Choose Industrial Air Services?

As a Dekker-authorized distributor and vacuum system specialist, Industrial Air Services delivers more than equipment—we provide end-to-end vacuum system solutions including:

On-site application consultation and sizing

Dekker pump and system selection

Installation and integration with existing systems

Preventive maintenance and 24/7 support

OEM parts, fluids, and training

Whether you're designing a new line or retrofitting an old one, we’ll help you choose and support the right Dekker vacuum pump for years to come.

📞 Call Industrial Air Services at (615) 641-3100 today to schedule a vacuum assessment or request a quote.

Conclusion

Choosing between a rotary vane and a liquid ring vacuum system depends on your specific process, gas composition, and operating conditions. Dekker Vacuum Technologies manufactures high-performance equipment in both categories, and with Industrial Air Services as your regional partner, you get the expertise, support, and service you need to make a smart, cost-effective choice.

Contact us at (615) 641-3100 or visit us in Nashville, Knoxville, or Chattanooga to learn more about how we can help you improve vacuum performance, reduce downtime, and maximize energy efficiency.

Choosing the Right Atlas Copco Vacuum Pump: A Complete Buyer’s Guide

Vacuum systems are critical to countless industrial processes—from food packaging to pharmaceutical manufacturing, plastics extrusion, semiconductor fabrication, and more. Choosing the right vacuum pump isn’t just about picking the most powerful option—it’s about selecting the pump that matches your process demands, energy goals, environmental requirements, and long-term operational strategy.

Atlas Copco offers one of the widest, most innovative selections of industrial vacuum pumps available today. In this guide, we’ll walk you through the key factors to consider when selecting a vacuum pump and explain how Industrial Air Services can help you design a solution optimized for success.

📞 Need expert help selecting the right vacuum system? Call Industrial Air Services at (615) 641-3100 for assistance across Nashville, Knoxville, and Chattanooga.

Why Selecting the Right Vacuum Pump Matters

Installing the wrong vacuum system can lead to

Wasted energy and inflated operating costs

Frequent maintenance and unexpected downtime

Inconsistent process quality and product defects

Overpaying for capacity you don’t need—or under-specifying and falling short

Choosing the right pump ensures

Lower total cost of ownership (TCO)

Stable, reliable process performance

Reduced energy consumption and carbon footprint

Simplified maintenance and better system longevity

Factors to Consider When Choosing a Vacuum Pump

Process Requirements

Start by understanding your process vacuum needs. Key parameters include

Required operating pressure (mbar or Torr)

Gas flow rate (ACFM or m³/h)

Gas type (clean air, vapor-laden, corrosive, or particulate)

Duty cycle (continuous, intermittent, heavy load variations)

Special conditions (explosive atmospheres, cleanroom standards)

Atlas Copco offers solutions that cover rough, medium, and high vacuum applications across all these conditions.

Pump Technology Options

Atlas Copco manufactures several types of vacuum pumps, including

Oil-Sealed Rotary Screw (GHS VSD⁺ Series)

High efficiency for continuous duty applications like bottling, plastics, woodworking, and packaging

Dry Screw (DWS VSD⁺ Series)

Oil-free, contamination-free solution ideal for food, pharma, and semiconductor applications

Dry Claw (DZS Series)

Low maintenance, energy-efficient, compact pumps for plastics, CNC machining, and pneumatic conveying

Liquid Ring (AWL, AWS, AWD Series)

Best suited for wet, vapor-heavy, or corrosive gas processes like chemical production, wastewater treatment, and power generation

Each technology offers specific advantages depending on the process.

Energy Efficiency Goals

Atlas Copco’s VSD⁺ (Variable Speed Drive) technology allows pumps to automatically adjust motor speed based on real-time demand—saving up to 50% on energy costs compared to fixed-speed alternatives.

If energy efficiency is a priority, prioritize pumps like the GHS VSD⁺, DWS VSD⁺, and LRP VSD⁺ Series models.

Maintenance Requirements

Consider how much time and labor you can allocate to system maintenance.

Dry claw and dry screw pumps offer lower maintenance needs compared to oil-sealed pumps, which require regular oil changes and filter replacements.

Smart monitoring options like GENIUS Instant Insights™ can further simplify maintenance by providing predictive alerts and performance dashboards.

Space Constraints and Installation Flexibility

If floor space is tight or if you need mobile, modular setups, choose compact systems like the DZS dry claw series or skid-mounted multi-pump systems.

Custom layouts from Atlas Copco’s Systems + Solutions team can optimize centralized vacuum plant installations for even the most challenging facilities.

Environmental or Safety Compliance

Industries like pharmaceuticals, semiconductors, and food production often require oil-free, clean vacuum systems to comply with ISO, FDA, EHEDG, or GMP standards.

Facilities handling flammable vapors or working in hazardous zones may require explosion-proof pumps, which Atlas Copco can provide across several product lines.

Popular Atlas Copco Vacuum Pump Options

GHS VSD⁺ Series

Oil-sealed rotary screw pumps with VSD⁺ energy-saving technology

Excellent for plastics, packaging, woodworking, and bottling industries

Highly efficient with low lifecycle costs

DWS VSD⁺ Series

Dry screw vacuum pumps with oil-free operation

Ideal for semiconductor, food, and pharmaceutical applications

Handles vapors and condensables with ease

DZS Dry Claw Series

Compact, low-maintenance claw pumps

Perfect for industrial processes like CNC support, conveying, and thermoforming

Simple to maintain and operate

LRP VSD⁺ Series

Liquid ring vacuum pumps built for wet and vapor-heavy conditions

Excellent in chemical, wastewater, and power applications

Built for rugged environments with maximum reliability

AWL, AWS, AWD Liquid Ring Series

Heavy-duty liquid ring solutions for highly corrosive or saturated gas environments

Designed for long life even in aggressive processes

How Industrial Air Services Helps You Select the Right Pump

Industrial Air Services offers a structured approach to vacuum system selection, including

On-site process evaluations and data logging

Vacuum demand profiling and application engineering

Energy savings calculations and lifecycle cost modeling

Custom system design, installation, and commissioning

Preventive maintenance programs and 24/7 emergency support

We combine Atlas Copco’s world-class technology with local, hands-on expertise to ensure you get the perfect vacuum solution—built to meet today’s needs and tomorrow’s growth.

📞 Ready to start your vacuum system evaluation? Call Industrial Air Services at (615) 641-3100 today.

Real-World Example: Medical Device Manufacturer in Chattanooga

A medical device manufacturer needed to replace outdated oil-sealed pumps in a cleanroom environment. Contamination risk was high, and downtime penalties were severe.

They switched to Atlas Copco DWS VSD⁺ dry screw pumps with GENIUS remote monitoring.

Results included

Zero product contamination from oil or particles

Energy savings of 36% compared to legacy equipment

Real-time performance monitoring reduced maintenance needs

Faster ramp-up times and more consistent process control

Today, the facility runs a fully oil-free, efficient vacuum system aligned with ISO 14644-1 cleanroom standards.

Key Tips for a Successful Vacuum System Purchase

Always evaluate actual process needs instead of oversizing "just in case."

Consider lifecycle costs, not just upfront equipment price.

Think long-term about maintenance, serviceability, and scalability.

Leverage digital tools like HEX@™ and GENIUS for smarter, more efficient operations.

Work with a trusted, experienced partner like Industrial Air Services.

Conclusion

Selecting the right vacuum pump is about more than specifications—it’s about understanding your full operational landscape and choosing a solution that improves efficiency, reliability, and profitability. Whether you need oil-free dry vacuum, rugged liquid ring performance, or energy-saving rotary screw technology, Atlas Copco and Industrial Air Services can deliver a vacuum system perfectly matched to your business.

Call Industrial Air Services at (615) 641-3100 today to schedule a site consultation or start designing your ideal vacuum solution across Nashville, Knoxville, and Chattanooga.

Understanding Dry Vacuum Technologies: Benefits of Screw and Claw Pumps

Modern industrial operations demand vacuum solutions that are not only reliable and energy-efficient but also clean, low maintenance, and environmentally sustainable. In industries like pharmaceuticals, food production, electronics, plastics, and research, contamination from oils or liquids is unacceptable. That's where dry vacuum technologies—specifically dry screw pumps and dry claw pumps—shine.

Atlas Copco, a global leader in vacuum solutions, offers some of the most advanced dry vacuum technologies on the market today. In this blog, we’ll explore the fundamentals of dry vacuum pumps, compare screw and claw technologies, and explain how partnering with Industrial Air Services ensures the right solution for your operation.

📞 Need help selecting the right dry vacuum system? Call Industrial Air Services at (615) 641-3100 for expert service across Nashville, Knoxville, and Chattanooga.

What Are Dry Vacuum Pumps?

Unlike oil-sealed rotary vane or liquid ring vacuum pumps, dry vacuum pumps achieve compression without using any liquid or oil inside the pumping chamber. This eliminates the risk of oil contamination and minimizes maintenance requirements.

Dry pumps operate by trapping gas and reducing its volume through the mechanical action of rotors, claws, or screws—without any internal lubrication.

Benefits of dry vacuum pumps include

Oil-free, contamination-free operation

Lower maintenance and cleaning requirements

Greater suitability for cleanroom and high-purity environments

Better energy efficiency for many industrial processes

Reduced waste and environmental impact

Atlas Copco’s dry vacuum lineup includes the DWS VSD⁺ dry screw pumps and the DZS Series dry claw pumps, both designed for maximum reliability and efficiency.

Understanding Dry Screw Vacuum Pumps

Dry screw vacuum pumps operate by using two intermeshing helical screws rotating in opposite directions. As the screws rotate, gas is trapped between the screw threads and moved toward the discharge port while being compressed.

Key features of dry screw pumps

High pumping speeds across a wide pressure range

Ability to handle condensable vapors and light particulate loads

Smooth, pulse-free gas flow for sensitive processes

Robust design suited for harsh, corrosive, or dirty gas streams

Atlas Copco’s DWS VSD⁺ models feature Variable Speed Drive (VSD⁺) technology, allowing motor speed to automatically adjust to real-time process demands—saving energy and extending equipment life.

Ideal applications for dry screw pumps

Pharmaceutical freeze drying (lyophilization)

Chemical vapor deposition (CVD) in semiconductor production

Food packaging and vacuum drying

Vacuum distillation and solvent recovery

Plastic extrusion and degassing

Understanding Dry Claw Vacuum Pumps

Dry claw vacuum pumps use two rotors with claw-shaped profiles rotating in opposite directions. Gas enters the compression chamber, is trapped between the claws, and is compressed as the claws rotate and approach the discharge port.

Key features of dry claw pumps

Extremely low maintenance (very few wearing parts)

Efficient design requiring minimal power input

Ability to handle humid or dusty gases

Highly compact and modular construction

Atlas Copco’s DZS Series claw pumps are known for rugged durability, compact footprint, and cost-effective operation in a variety of industrial settings.

Ideal applications for dry claw pumps

Pneumatic conveying systems

Plastics thermoforming and molding

Woodworking CNC machine support

Food processing (conveying, pick-and-place)

Environmental remediation (soil vapor extraction)

Real-World Example: Semiconductor Cleanroom in Nashville

A semiconductor fabrication facility required ultra-clean, oil-free vacuum for their etching and wafer processing operations. Contamination from traditional oil-sealed pumps was unacceptable.

They installed Atlas Copco DWS VSD⁺ dry screw pumps with HEX@™ smart controls and GENIUS Instant Insights™ remote monitoring.

Results included

Maintained ISO 6 cleanroom standards without risk of contamination

Energy savings of 30% through VSD⁺ dynamic control

Zero vacuum pump-related downtime in 18 months

Improved product yields and reduced defect rates

📞 Need similar clean vacuum solutions? Call Industrial Air Services at (615) 641-3100 today.

Advantages of Atlas Copco’s Dry Vacuum Technologies

VSD⁺ Standardization

All Atlas Copco dry screw and claw pumps with VSD⁺ technology automatically adjust motor speed to real-time demand, drastically reducing energy use.

Compact, Modular Design

Atlas Copco’s DWS and DZS pumps are designed for easy installation, small footprints, and flexible system integration.

Smart Monitoring

With GENIUS Instant Insights™ remote monitoring and HEX@™ touchscreen controls, you can manage your vacuum system more efficiently and proactively.

Low Noise and Vibration

Dry claw and screw technologies operate quietly, improving workplace environments and reducing the need for costly acoustic enclosures.

Environmentally Friendly

No oil contamination, reduced emissions, and lower energy consumption help facilities meet stringent environmental regulations and corporate ESG goals.

Maintenance Best Practices for Dry Vacuum Pumps

Follow recommended service intervals for inspections and preventive maintenance

Replace shaft seals and check rotor clearances as needed (especially for dry screw pumps)

Keep cooling fins and air filters clean to maintain optimal temperatures

Use Atlas Copco OEM parts and fluids for any maintenance to preserve warranty and performance

Set up remote monitoring through GENIUS to catch small issues before they escalate

How Industrial Air Services Supports Your Dry Vacuum System

Industrial Air Services provides full support for Atlas Copco dry vacuum systems, including

Site audits and application consulting

System design, installation, and commissioning

Preventive maintenance contracts

24/7 emergency service and rapid response

GENIUS system setup and remote monitoring training

With local service teams in Nashville, Knoxville, and Chattanooga, we ensure your vacuum systems stay optimized and operational at all times.

📞 Ready to upgrade to oil-free dry vacuum technology? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Dry vacuum technologies, including screw and claw pumps, are revolutionizing industrial operations by offering contamination-free, energy-efficient, and low-maintenance vacuum solutions. Whether you need high pumping speed for pharmaceutical manufacturing or rugged reliability for plastics extrusion, Atlas Copco’s dry vacuum systems provide the performance and peace of mind modern industries demand. With Industrial Air Services as your trusted partner, you’ll have the local support and engineering expertise needed to design, install, and maintain your ideal vacuum solution.

Contact Industrial Air Services at (615) 641-3100 to get started with a site evaluation or discuss upgrading your vacuum systems across Nashville, Knoxville, and Chattanooga.

Custom Vacuum Systems: Tailored Solutions for Complex Industrial Needs

No two industrial facilities are exactly alike. Each plant has unique processes, layouts, operating conditions, and production goals. When it comes to vacuum systems, a standard off-the-shelf solution often falls short. That’s why custom vacuum system engineering has become essential for companies seeking maximum reliability, energy efficiency, and process optimization.

Atlas Copco leads the industry in providing fully engineered, customized vacuum solutions designed to meet the specific challenges of your operation. Backed by the expertise of Industrial Air Services, custom vacuum systems are no longer a luxury—they're a competitive advantage.

📞 Need a vacuum system built specifically for your needs? Call Industrial Air Services at (615) 641-3100 for expert consultation in Nashville, Knoxville, and Chattanooga.

Why Custom Vacuum Systems Are Necessary

Every production process demands specific vacuum characteristics. Factors like required flow rates, ultimate pressure, vapor loads, chemical exposure, system redundancy, and control integration all affect the design.

Choosing a standard system without considering these variables often results in

Oversized or undersized vacuum pumps wasting energy or failing to meet demand

Frequent maintenance due to incompatible process conditions

Complex installations requiring expensive retrofits

Limited ability to scale production up or down

Higher operational and repair costs over time

Custom-engineered vacuum systems ensure that every component—from the pumps to the controls—is perfectly matched to your real-world requirements.

Key Components of a Custom Vacuum System

A tailored vacuum solution typically includes

Accurately sized vacuum pumps for flow and pressure needs

Centralized or distributed piping and vacuum headers

Redundancy for critical applications where uptime is essential

Custom control panels, HMI displays, and automation integration

Remote monitoring capabilities through platforms like GENIUS Instant Insights™

Energy recovery systems where applicable

Noise and vibration mitigation strategies for workplace comfort

Space-optimized layouts for easy installation and maintenance

Atlas Copco’s broad vacuum product portfolio, combined with Systems + Solutions engineering expertise, makes it possible to create fully customized solutions for virtually any industrial sector.

Examples of Industries That Benefit from Custom Vacuum Systems

Pharmaceuticals

Critical applications like freeze-drying, sterile product handling, and coating processes demand extremely clean, oil-free vacuum solutions with precise control.

Electronics and Semiconductor Manufacturing

Wafer fabrication, photolithography, and vacuum deposition require ultra-high vacuum levels, cleanroom compatibility, and minimal contamination risk.

Food and Beverage

Modified atmosphere packaging (MAP), bottling, dairy processing, and evaporation systems benefit from centralized, energy-efficient vacuum designs that maximize uptime.

Plastics and Rubber

Extrusion, thermoforming, and degassing processes rely on vacuum consistency to maintain product quality and reduce scrap rates.

Power Generation and Energy

Transformer drying, turbine evacuation, and other processes need robust, moisture-resistant vacuum systems engineered for high uptime.

Printing and Packaging

Printing presses and flexible packaging machines operate more efficiently and consistently with vacuum systems tuned to precise operating pressures and duty cycles.

Atlas Copco’s Approach to Custom Vacuum System Design

Site Assessment and Data Collection

Industrial Air Services and Atlas Copco engineers conduct on-site evaluations, reviewing process requirements, facility layout, load variations, and energy consumption patterns.

System Modeling and Simulation

Using advanced modeling software, engineers simulate different vacuum system configurations to find the most energy-efficient, cost-effective design.

Component Selection

Atlas Copco’s extensive lineup of vacuum pumps—including GHS VSD⁺ rotary screw, DWS VSD⁺ dry screw, LRP VSD⁺ liquid ring, and DZS dry claw pumps—ensures the perfect match for each application.

Control System Design

HEX@™ smart interfaces and GENIUS Instant Insights™ remote monitoring can be integrated for superior operational control and predictive maintenance.

Installation Planning

Custom skids, modular system designs, and optimized piping layouts simplify installation and allow for future scalability.

Training and Ongoing Support

Industrial Air Services provides training for your team and offers preventive maintenance programs to ensure your system delivers peak performance year after year.

Real-World Example: Chemical Plant Vacuum Upgrade in Knoxville

A chemical manufacturing facility needed to upgrade an aging vacuum system supporting solvent recovery and distillation operations. Their legacy setup used multiple small oil-sealed pumps scattered across the plant floor, leading to

High energy costs

Frequent maintenance and inconsistent vacuum levels

Noise issues disrupting production staff

Industrial Air Services worked with Atlas Copco’s Systems + Solutions team to design a centralized vacuum system featuring

Three GHS VSD⁺ rotary screw pumps with automatic load balancing

Custom stainless-steel piping and headers

Integrated GENIUS remote monitoring for early warning alerts

Redundant pump setup for 100% uptime coverage

Results after installation

Energy savings of 42% compared to the old system

Reduced maintenance costs by 35%

Improved product yield through stable vacuum control

📞 Interested in a similar custom solution? Call Industrial Air Services at (615) 641-3100 today.

Advantages of Custom-Engineered Vacuum Systems

Lower Total Cost of Ownership

Correctly sized and configured systems use less energy, require less maintenance, and last longer.

Higher Reliability and Uptime

Built-in redundancy and proactive monitoring minimize downtime risks.

Optimized Process Efficiency

Precise vacuum control improves product quality and reduces scrap.

Scalability

Custom systems are easier to expand or modify as production needs evolve.

Compliance and Safety

Customized designs ensure compatibility with cleanroom standards, explosion-proof requirements, or hazardous material handling regulations.

How Industrial Air Services Supports Custom Systems

Industrial Air Services is your local Atlas Copco expert for customized vacuum system design and support. Our services include

Site evaluations and system sizing

Full CAD and modeling support for custom layouts

Installation and commissioning

Training for operators and maintenance teams

Preventive maintenance contracts and emergency service

Our goal is not just to sell equipment—it’s to deliver vacuum solutions that help our customers grow, optimize costs, and achieve long-term success.

📞 Want to design a custom vacuum solution for your facility? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Custom vacuum systems are the future of efficient, reliable, and sustainable industrial operations. Whether you need to streamline energy use, improve product quality, or eliminate downtime risks, a properly engineered Atlas Copco system can deliver major performance and financial advantages. With Industrial Air Services as your local partner, you’ll have the expertise needed to design, install, and maintain a custom vacuum system built for your success.

Call Industrial Air Services at (615) 641-3100 to schedule a consultation or site walkthrough in Nashville, Knoxville, or Chattanooga.

Best Practices for Vacuum Pump Maintenance: How to Extend Equipment Life and Maximize ROI

Industrial vacuum pumps are critical assets in manufacturing, food production, pharmaceutical operations, electronics fabrication, and countless other sectors. Yet despite their importance, vacuum pumps are often overlooked when it comes to proactive maintenance. Unfortunately, neglecting these vital machines leads to unnecessary downtime, costly repairs, and reduced equipment lifespan.

Proper vacuum pump maintenance isn't just about preventing failures—it’s about maximizing return on investment (ROI), optimizing energy efficiency, and ensuring process reliability. In this blog, we’ll break down proven maintenance best practices and explain how Industrial Air Services and Atlas Copco can help you protect your vacuum systems and your bottom line.

📞 Need help with a preventive maintenance program? Call Industrial Air Services at (615) 641-3100 for service across Nashville, Knoxville, and Chattanooga.

The High Cost of Neglecting Vacuum Pump Maintenance

Vacuum pumps operate in demanding conditions—handling vapors, contaminants, fluctuating loads, and continuous-duty cycles. Without routine care, small issues snowball into major problems.

Costs of poor maintenance include

Unplanned downtime and production losses

Emergency repair expenses and expedited parts orders

Reduced pump efficiency leading to higher energy bills

Contamination of process materials (critical in pharma, food, and electronics)

Premature equipment replacement costing tens of thousands of dollars

The good news is that implementing a structured maintenance strategy can dramatically reduce these risks.

Best Practices for Vacuum Pump Maintenance

Follow Manufacturer Service Schedules

Every vacuum pump comes with a recommended maintenance schedule based on operating hours, duty cycle, and environmental conditions. Key intervals typically include

Oil changes (for oil-sealed pumps) every 2,000 to 4,000 hours

Filter inspections or replacements every 3 to 6 months

Seal inspections and lubrication checks every 6 to 12 months

Major overhauls every 20,000 to 40,000 hours depending on pump type

Following these schedules prevents unexpected failures and extends pump life.

Monitor Performance Indicators

Pay close attention to key indicators like

Increasing operating temperature

Rising motor current draw

Fluctuations in vacuum pressure levels

Unusual vibrations or noises

Oil condition and contamination levels

Using smart monitoring platforms like Atlas Copco’s GENIUS Instant Insights™ provides real-time data to detect early signs of wear or failure.

Keep the Pump Clean

Dirt, dust, and debris can clog cooling fins, filters, and valves—causing overheating and reduced efficiency. Regular cleaning of external surfaces and filter elements is a simple but essential maintenance task.

Inspect Seals and Gaskets

Leaks compromise vacuum performance and introduce contaminants into the system. Check mechanical seals, shaft seals, and gasket joints during routine inspections and replace worn components promptly.

Use OEM Parts and Fluids

Using non-OEM parts or off-brand fluids may seem like a cost-saving move but often leads to accelerated wear, compatibility issues, and warranty voidance. Always use Atlas Copco-approved oil, filters, seals, and spare parts to maintain optimal performance and protect your investment.

Implement a Preventive Maintenance Plan

Rather than waiting for a problem to arise, implement a structured preventive maintenance (PM) plan that includes

Regular oil analysis

Performance trend monitoring

Scheduled filter changes

Annual or semi-annual full system inspections

Component wear measurements (bearings, vanes, rotors)

Industrial Air Services offers preventive maintenance contracts tailored to your equipment and production schedule, ensuring consistent care without overburdening your internal maintenance team.

Benefits of a Strong Vacuum Pump Maintenance Program

Longer Equipment Life

Well-maintained vacuum pumps often operate reliably for 10 to 15 years or more—delivering an outstanding return on your initial investment.

Reduced Downtime

Preventive maintenance minimizes unexpected breakdowns and emergency outages, keeping production lines running smoothly.

Lower Energy Costs

Clean, properly lubricated, and leak-free vacuum pumps operate more efficiently—reducing electrical consumption and cutting operating expenses.

Improved Process Quality

Stable, consistent vacuum levels ensure high product quality, especially in sensitive applications like food packaging, electronics manufacturing, and pharmaceutical production.

Faster ROI

By extending equipment life, reducing repair costs, and improving efficiency, preventive maintenance delivers measurable financial returns.

Real-World Example: Food Packaging Plant in Tennessee

A regional food processor was experiencing frequent vacuum pump failures on their MAP (Modified Atmosphere Packaging) lines. Each downtime event cost the plant thousands of dollars in lost production and emergency service calls.

Industrial Air Services implemented a comprehensive preventive maintenance program for their Atlas Copco GHS VSD⁺ rotary screw pumps, including

Quarterly system inspections

Oil analysis every 2,000 hours

Annual seal replacement program

Remote monitoring through GENIUS Instant Insights™

Results after 12 months

Zero unplanned vacuum pump downtime

Energy savings of 18% through setpoint optimization

Increased pump lifespan projections by 6–8 years

📞 Want similar results? Call Industrial Air Services at (615) 641-3100 today.

Common Maintenance Mistakes to Avoid

Skipping Routine Inspections

Small leaks, clogged filters, and oil contamination are easy to fix if caught early but become costly if ignored.

Using the Wrong Fluids

Not all oils are the same. Atlas Copco vacuum pumps are engineered to operate with specific fluids that resist oxidation, foaming, and vapor carryover.

Ignoring Minor Changes

Changes in sound, vibration, or vacuum pressure are early warnings. Investigating small issues prevents big repairs.

Delaying Preventive Maintenance

Trying to "stretch" service intervals may seem economical but often leads to higher costs over time due to accelerated wear and unplanned failures.

Why Partner with Industrial Air Services

Industrial Air Services is your local Atlas Copco vacuum expert. We offer

Certified preventive maintenance and repair services

Customized PM programs based on your process needs

GENIUS Instant Insights™ setup and remote monitoring support

OEM parts and fluids stocked locally for faster service

24/7 emergency support across Nashville, Knoxville, and Chattanooga

We don't just maintain equipment—we build long-term partnerships focused on maximizing your uptime and operational success.

📞 Ready to protect your vacuum systems and maximize ROI? Call Industrial Air Services at (615) 641-3100 today.

Conclusion

Vacuum pumps are vital to your operations, and protecting them with a strong preventive maintenance program is one of the smartest investments you can make. From extending equipment life to cutting energy costs and preventing downtime, the benefits are clear. With Industrial Air Services and Atlas Copco’s industry-leading vacuum technologies, you can ensure that your systems stay reliable, efficient, and ready to support your business goals for years to come.

Contact Industrial Air Services at (615) 641-3100 today to schedule a maintenance consultation or learn more about how we can help optimize your vacuum operations across Nashville, Knoxville, and Chattanooga.

GENIUS Instant Insights™: How Remote Monitoring is Revolutionizing Vacuum Pump Management

Industrial facilities depend on vacuum systems for critical operations across manufacturing, packaging, chemical processing, food production, and electronics. But when a vacuum pump fails without warning, the result is costly downtime, product losses, and emergency repairs. Today, thanks to advancements in digital technology, predictive maintenance and remote system management are transforming how facilities manage their vacuum equipment.

Atlas Copco’s GENIUS Instant Insights™ platform is at the forefront of this shift. By providing real-time remote monitoring, performance data, and predictive alerts, GENIUS helps businesses avoid costly downtime, improve energy efficiency, and make smarter maintenance decisions.

In this blog, we'll explore how GENIUS Instant Insights™ works, the benefits it delivers, and why partnering with Industrial Air Services ensures your facility gets the most from your Atlas Copco vacuum systems.

📞 Want to learn how GENIUS can protect your operations? Call Industrial Air Services at (615) 641-3100 for support in Nashville, Knoxville, and Chattanooga.

The High Cost of Unplanned Downtime

Vacuum pump failures can happen for many reasons, including seal wear, overheating, bearing failure, or contamination. Without early warning, these failures often cause

Unexpected production stoppages

Expensive emergency repair costs

Product scrap or quality issues

Increased energy waste as pumps struggle

Higher maintenance labor costs

Studies show that the average unplanned downtime event costs between $2,500 and $25,000 per hour depending on the industry. Proactively monitoring equipment health is the most effective way to prevent these disasters—and GENIUS Instant Insights™ is specifically designed to do just that.

What Is GENIUS Instant Insights™?

GENIUS Instant Insights™ is Atlas Copco’s cloud-based platform for vacuum pump monitoring and diagnostics. Installed sensors gather data from your vacuum equipment, which is then transmitted securely to the cloud where it is analyzed in real time.

Key capabilities include

Live performance dashboards accessible from anywhere

Early warning notifications for maintenance needs or abnormal conditions

Energy consumption and system efficiency tracking

Automated maintenance scheduling and reminders

Historical data and trend analysis for smarter decision-making

With GENIUS, facilities gain visibility into their vacuum systems like never before—without the need for manual inspections or local data loggers.

How GENIUS Works

Connected Sensors

Atlas Copco vacuum pumps like the GHS VSD⁺, DWS VSD⁺, and DHS series are factory-equipped or easily retrofitted with GENIUS-compatible sensors that monitor parameters such as pressure, temperature, motor load, vibration, and oil condition.

Secure Cloud Transmission

Collected data is securely transmitted to the Atlas Copco cloud using encrypted communications, ensuring your information is safe.

Real-Time Analysis

Advanced algorithms analyze data patterns to detect anomalies, performance degradation, and early signs of component wear.

Actionable Alerts

When issues are detected, GENIUS sends instant notifications to maintenance teams via email, text, or through the dashboard—allowing fast, informed action.

Benefits of Using GENIUS Instant Insights™

Prevent Unplanned Downtime

By identifying early warning signs of potential failures, GENIUS enables planned maintenance instead of reactive repairs. This can reduce emergency breakdowns by up to 60%.

Optimize Energy Usage

Monitoring motor loads, system leaks, and pressure setpoints helps optimize energy consumption—leading to measurable reductions in operating costs.

Extend Equipment Life

Proactive maintenance and smoother system operation mean pumps last longer, reducing capital equipment replacement costs.

Simplify Maintenance Management

Automated scheduling and clear maintenance timelines take the guesswork out of servicing vacuum pumps, freeing up your maintenance staff for other priorities.

Gain 24/7 Access Anywhere

Access system dashboards from any web-enabled device, whether you’re on the plant floor, in the office, or working remotely.

Support ESG and Sustainability Goals

By minimizing wasted energy and material losses, GENIUS contributes to lower carbon footprints and improved corporate sustainability reporting.

Real-World Example: Semiconductor Manufacturer in Tennessee

A semiconductor production facility operating multiple cleanrooms needed continuous uptime and strict control over vacuum performance. Manual inspections were labor-intensive and often missed early warning signs of trouble.